When selecting a ball valve for an industrial application, two of the most common types are top entry ball valves and side entry ball valves. Each of these designs has its unique features, advantages, and disadvantages, making them better suited to specific applications. Understanding the differences between these two valve types can help you choose the right one for your system, based on factors like ease of maintenance, flow requirements, and pressure ratings.

In this guide, we’ll explore the key differences between top entry and side entry ball valves, discussing their design, operation, advantages, and ideal applications.

What Is a Ball Valve?

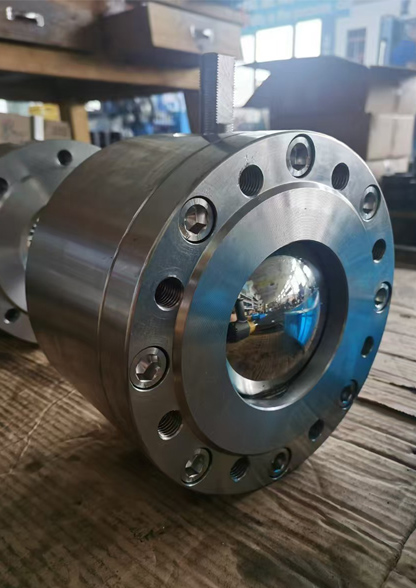

Before diving into the differences, let’s first define what a ball valve is. A ball valve is a quarter-turn valve that uses a hollow, perforated ball to control the flow of a fluid. The ball rotates inside the valve body to either allow or block flow. Ball valves are known for their fast operation, reliability, and ability to provide a tight seal, making them widely used in various industries, including oil and gas, chemical processing, water treatment, and more.

1. Top Entry Ball Valve: Design and Function

A top entry ball valve is a type of valve in which the ball and its internal components are accessed from the top of the valve body. This design is often used in larger valves, where ease of maintenance and access to the internal parts are a priority.

Key Features:

Access from the Top: The most distinguishing feature of the top entry ball valve is that the valve can be disassembled and serviced by removing the bonnet or cover from the top of the valve body.

Valve Internals: The valve ball, seats, and stem are all accessible from the top. This allows for easy replacement of the internal components without removing the entire valve from the pipeline.

Sealing: The valve uses a sealant to ensure a tight, leak-proof closure when the ball is in the closed position.

Advantages of Top Entry Ball Valves:

Ease of Maintenance: Maintenance is more straightforward since there is no need to remove the valve from the pipeline. Only the top cover needs to be removed, making it ideal for large valves or systems that require frequent maintenance.

Minimal Disruption: Since the valve does not have to be disconnected from the pipeline, there is less downtime during maintenance or repairs.

Suitable for High Pressure/Temperature: Top entry ball valves are often used in applications with high-pressure or high-temperature fluids because the design is more robust and can handle demanding conditions.

Ideal Applications:

Large-scale operations like power plants, oil refineries, or chemical processing plants.

Applications where valve internals need to be accessed for maintenance without interrupting the entire system.

2. Side Entry Ball Valve: Design and Function

In a side entry ball valve, the ball and its components are accessed from the side of the valve body. This is the more traditional design for most smaller ball valves and is commonly found in applications that don’t require frequent internal access.

Key Features:

Access from the Side: The internals of the valve (ball, stem, and seals) are accessible from the side of the valve body. In most cases, the valve must be removed from the pipeline to perform maintenance.

Compact Design: Side entry ball valves typically have a more compact and cost-effective design compared to top entry valves.

Ball and Seal Configuration: The ball valve is mounted in a body that allows the ball to rotate and block or allow flow through the valve ports.

Advantages of Side Entry Ball Valves:

Compact and Economical: The side entry design is simpler, making it less expensive and ideal for smaller valve sizes or systems with fewer maintenance needs.

Easier Installation: Because the design is generally more compact, side entry ball valves are often easier and faster to install.

Suitable for Lower Pressure/Temperature: Side entry ball valves are typically used in systems with lower pressure and temperature requirements compared to top entry valves.

Ideal Applications:

Smaller scale systems such as HVAC (Heating, Ventilation, and Air Conditioning), water treatment plants, or food processing industries.

Systems that do not require frequent maintenance or where quick and simple installation is needed.

Key Differences Between Top Entry and Side Entry Ball Valves

|

Feature |

Top Entry Ball Valve |

Side Entry Ball Valve |

|

Access to Internals |

Access from the top, easier to service and replace components without removing the valve from the pipeline. |

Access from the side, typically requiring removal of the valve from the pipeline for maintenance. |

|

Design Complexity |

More complex design, typically used for larger valves or in high-pressure systems. |

Simpler, more compact design, typically used for smaller valves or less complex applications. |

|

Maintenance |

Easier to maintain since only the top portion needs to be removed. |

Requires valve removal from the pipeline for maintenance. |

|

Cost |

Generally more expensive due to complex design and ease of maintenance. |

Typically more economical and cost-effective, especially for smaller valves. |

|

Size Range |

Commonly used for larger valves (2" and above). |

Typically used for smaller valves (below 2" or 4"). |

|

Pressure and Temperature |

Ideal for high-pressure and high-temperature applications. |

Suitable for lower pressure and temperature conditions. |

|

Applications |

Used in heavy-duty industries like oil & gas, chemical plants, and power generation. |

Common in industries like HVAC, water treatment, and food processing. |

When to Choose a Top Entry Ball Valve

A top entry ball valve is ideal for:

Heavy-duty applications: Industries like oil and gas, power generation, and petrochemical plants require robust valves that can handle extreme conditions.

Frequent maintenance: If you need to access the internal components of the valve regularly, the top entry design minimizes system downtime.

Large valve sizes: For larger valves (e.g., 3" and above), top entry ball valves are typically preferred because they are easier to maintain and provide better structural integrity.

When to Choose a Side Entry Ball Valve

A side entry ball valve is ideal for:

Compact systems: Side entry valves are great for smaller applications or systems where space is a concern.

Low to medium-pressure applications: If your application doesn’t involve extreme pressures or temperatures, side entry ball valves can provide an effective, economical solution.

Simpler installations: In situations where quick installation and minimal complexity are important, side entry ball valves offer the right solution.

Conclusion: Which One Should You Choose?

Both top entry and side entry ball valves have their unique advantages and are suited for different applications. When choosing between the two, it ultimately comes down to factors like:

The size and pressure requirements of your system.

Whether frequent maintenance is needed.

The complexity and cost of the valve design.

For larger systems and critical applications where maintenance is frequent, top entry ball valves provide superior performance. On the other hand, for smaller systems or applications with less demanding conditions, side entry ball valves offer a simpler, more economical solution.

By understanding the design differences and knowing your application requirements, you can choose the right type of ball valve to ensure optimal performance, safety, and cost-effectiveness for your system.