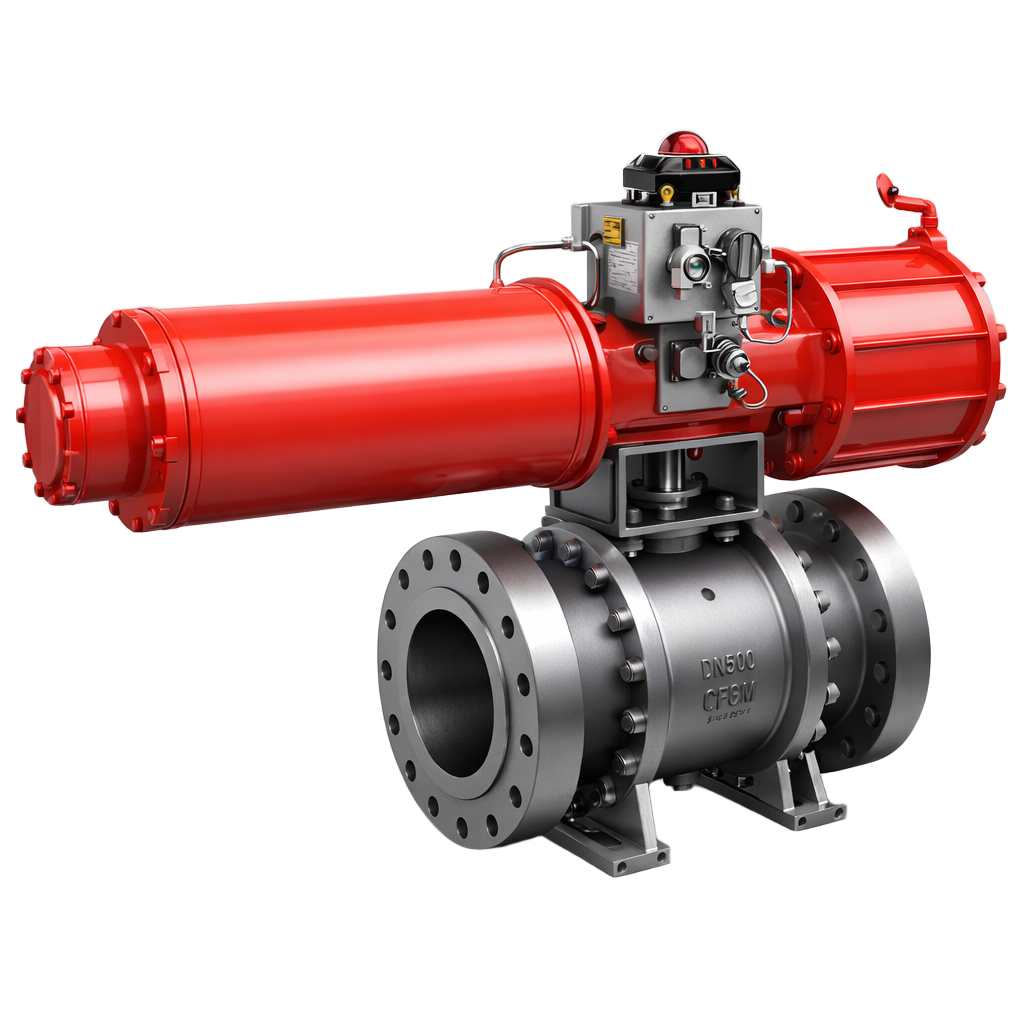

Pneumatic Ball Valve Proven Automation Solution for Reliable Flow Control A Pneumatic Ball Valve is a quarter-turn automated valve operated by a pneumatic actuator, widely used in industrial pipeline systems for fast, safe, and reliable flow control. Powered by compressed air, pneumatic ball valves are especially suitable for applications requiring high switching frequency, operational safety, and integration with automated control systems . How Pneumatic Ball Valves Work Pneumatic ball valves use a rack-and-pinion or scotch yoke actuator to convert air pressure into rotary motion. This design ensures consistent torque output and precise valve positioning, even under high-pressure or demanding operating conditions. Their simple operating principle contributes to long service life, stable performance, and low failure rates , making them a preferred choice in critical industrial processes. Key Performance Advantages Fast Response & Operational Efficiency Quarter-turn operation enables rapid open/close action, minimizing process downtime and improving system responsiveness. High Safety in Hazardous Environments As air-driven devices, pneumatic ball valves eliminate e ...

Read More

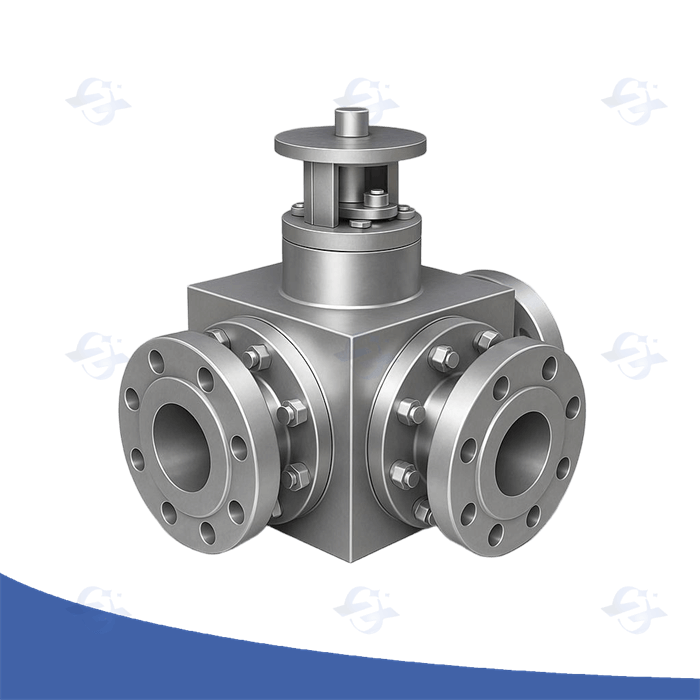

3 Way Ball Valve – Overview A 3 way ball valve is a versatile flow control device designed to divert, mix, or isolate fluids within a single pipeline system. Unlike standard two-way valves, a three-way configuration features an L-port or T-port ball design, allowing for more complex flow patterns and reducing the need for multiple valves. Design & Construction Flow Configurations L-Port : Redirects flow between two outlets. T-Port : Allows mixing or splitting of flow to multiple outlets. Material Options Carbon Steel – Excellent for general industrial use. Stainless Steel – Corrosion-resistant for chemical, food, and pharmaceutical applications. PVC or CPVC – Lightweight and chemical-resistant for low-pressure, non-metallic systems. Connection Types Available in threaded, flanged, or welded ends to match different piping standards (ANSI, DIN, JIS). Seating Materials PTFE, RPTFE, or metal seats for compatibility with temperat ...

Read More

Pigging Valves – Comprehensive Overview Overview A Pigging Valve is an integrated device combining the functions of a pig launcher/receiver and a valve. It is widely used in crude oil, refined products, natural gas, and chemical pipeline systems for pipeline cleaning, internal inspection, and maintenance without dismantling the pipeline. Compared to traditional pig launchers and receivers, pigging valves are compact, space-saving, and allow fast pig launching or receiving, improving operational safety and efficiency. Key functions: Launching or receiving pipeline pigs Removing deposits such as wax, scale, or rust from pipeline interiors Supporting in-line inspection pigs for pipeline integrity assessment Reducing operational footprint and installation cost Working Principle The pigging valve has a specially designed internal chamber and switching mechanism. When open, the valve aligns the pig chamber with the pipeline bore, allowing the pig to enter or exit the line. When closed, the chamber is isolated from the pipeline, enabling safe loading or removal of the pig. ...

Read More

Integral Block and Bleed Valves – Comprehensive Overview Integral Block and Bleed Valves are compact, high-integrity valve assemblies designed to isolate and vent process fluids in a single, integrated unit. Unlike traditional multi-valve arrangements, the block and bleed function is built directly into the valve body, reducing the number of potential leak paths, simplifying installation, and improving overall system safety. These valves are widely used in instrumentation systems, chemical processing, and energy production where precision and reliability are essential. Typical Operating Conditions Integral block and bleed valves are commonly applied in situations requiring both secure isolation and controlled venting: Instrumentation Lines – Isolating pressure transmitters, gauges, and switches for maintenance or calibration without shutting down the main process. Chemical Injection Systems – Preventing backflow and ensuring safe disconnection of injection lines. Hydraulic and Pneumatic Control Panels – Providing quick shutoff and venting in control circuits. Sampling Systems – Allowing safe withdrawal of process ...

Read More

Forged Steel Trunnion Mounted Ball Valve – Comprehensive Overview A forged steel trunnion mounted ball valve is a heavy-duty valve designed for reliable shutoff and control in high-pressure, high-temperature, and demanding process conditions. Unlike floating ball designs, the ball in a trunnion-mounted configuration is supported at both the top and bottom, reducing operating torque and minimizing seat wear. The use of forged steel enhances mechanical strength, structural integrity, and resistance to pressure-induced deformation, making these valves ideal for critical applications in the oil & gas, petrochemical, power generation, and industrial sectors. Typical Operating Conditions Forged steel trunnion mounted ball valves are commonly used in: High-Pressure Pipelines – Transporting crude oil, natural gas, refined products, and chemical fluids. Offshore and Subsea Systems – Handling extreme pressure, corrosive seawater exposure, and space-limited environments. Refineries and Petrochemical Plants – Isolating and controlling process fluids in hydrocracking, reforming, and catalytic units. Power Plants – Managi ...

Read More

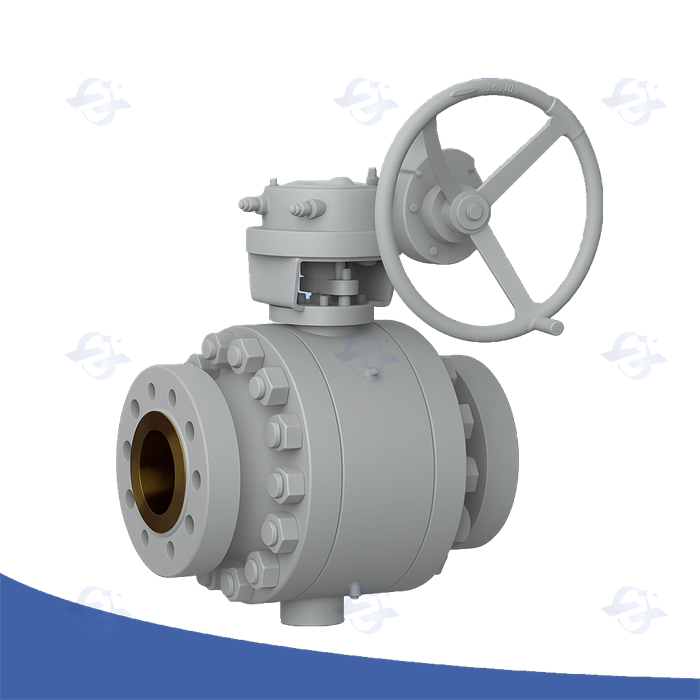

2PCS Cast Steel Trunnion Mounted Ball Valve – Comprehensive Overview A 2PCS cast steel trunnion mounted ball valve is a robust, high-performance valve designed for secure isolation and control in demanding industrial applications. The "2PCS" designation refers to its two-piece split body construction , which allows easier access to internal components for maintenance and inspection. The trunnion-mounted design supports the ball from both the top and bottom, reducing seat wear and operational torque, while the cast steel body provides excellent strength and cost efficiency for large-size, high-pressure service. Typical Operating Conditions This valve type is widely used in: Oil & Gas Transmission Pipelines – For onshore and offshore hydrocarbon transportation. Petrochemical and Refining Units – Managing high-pressure process streams in cracking, distillation, and reforming plants. Power Generation Facilities – Controlling steam, feedwater, and cooling circuits. LNG and Cryogenic Applications – Configurable with low-temperature trims and seals for liquefied gas handling. Water and Slu ...

Read More

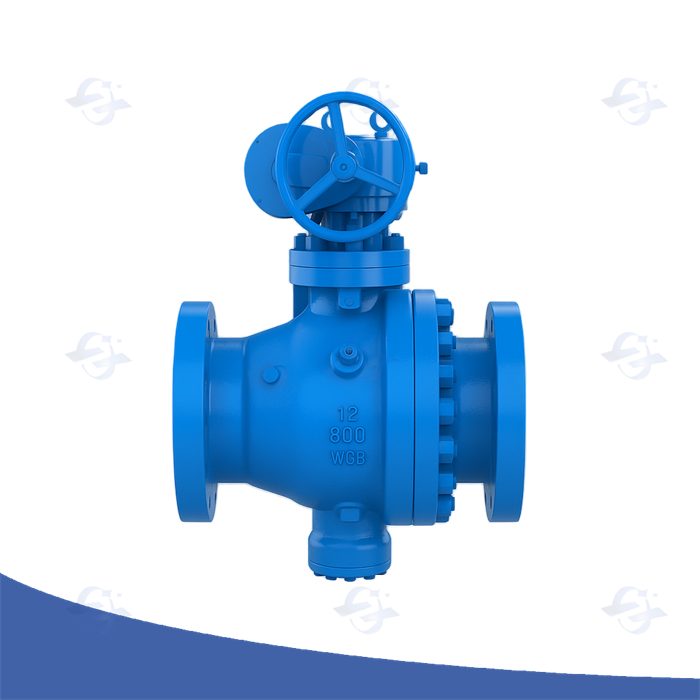

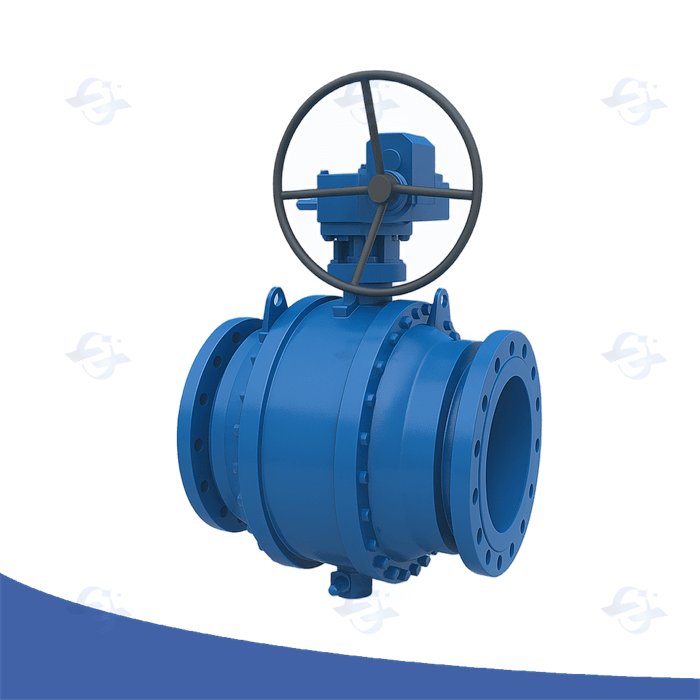

3PCS Cast Steel Trunnion Mounted Ball Valve – Comprehensive Overview A 3PCS cast steel trunnion mounted ball valve is a heavy-duty isolation valve designed for high-pressure and high-temperature service in critical industrial applications. The “3PCS” designation refers to its three-piece bolted body construction —two end caps and a central body section—which allows for inline maintenance and easier replacement of internal components without removing the entire valve from the pipeline. The trunnion-mounted design supports the ball from both the top and bottom, reducing operational torque and seat wear, while the cast steel body offers strength, manufacturing flexibility, and cost-effectiveness for large-size valves. Typical Operating Conditions 3PCS cast steel trunnion mounted ball valves are widely used in: Oil & Gas Transmission and Distribution – Providing secure shutoff in crude oil, refined products, and natural gas pipelines. Offshore Platforms and Subsea Installations – Handling extreme pressure, corrosive seawater, and tight installation spaces. Petrochemical and Refining Units – Managing high-temperature and ...

Read More

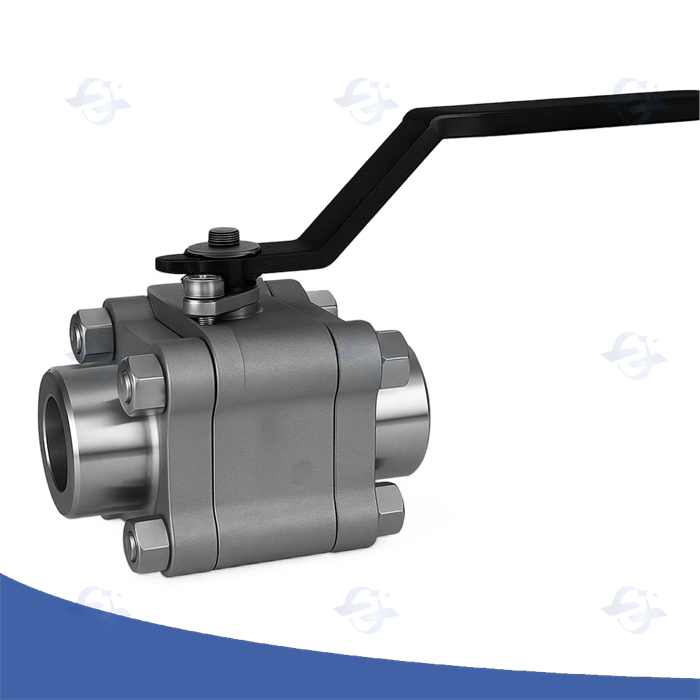

3PCS Forged Steel Floating Ball Valve – Comprehensive Overview A 3PCS forged steel floating ball valve is a compact, high-integrity shutoff valve designed for medium to high-pressure service in industrial process systems. The three-piece body construction —two end caps and a central body—allows inline maintenance and easy replacement of internal components without fully removing the valve from the pipeline. In a floating ball design , the ball is not fixed to the stem; instead, it moves slightly downstream under pressure to achieve a tight seal against the seat. The forged steel body provides exceptional strength, structural density, and resistance to mechanical stress, making this valve ideal for demanding conditions where durability and sealing reliability are critical. Typical Operating Conditions 3PCS forged steel floating ball valves are widely used in: Oil & Gas Processing Plants – Isolating process lines, manifolds, and utility services. Chemical and Petrochemical Plants – Handling aggressive media, solvents, and high-purity process fluids. Power Generation – Managing steam, condensate, and auxiliary systems. ...

Read More

Cryogenic Ball Valve – Comprehensive Overview A cryogenic ball valve is a specialized isolation valve designed to operate at extremely low temperatures, typically ranging from -196°C (-321°F) up to ambient temperature . These valves are engineered to handle liquefied gases such as LNG, liquid nitrogen, liquid oxygen, liquid hydrogen, and other cryogenic fluids, ensuring safe and reliable shutoff while preventing leakage during storage, transfer, and processing. Unlike standard ball valves, cryogenic designs incorporate extended stems to keep the stem packing away from the cold zone, reducing heat transfer and preventing seal damage from thermal contraction. Special seat and body materials are selected to maintain toughness, sealing integrity, and dimensional stability under cryogenic conditions. Typical Operating Conditions Cryogenic ball valves are widely used in: LNG Terminals and Storage Tanks – Isolating pipelines and transfer lines for liquefied natural gas. Air Separation Units – Controlling the flow of liquid oxygen, nitrogen, and argon. Hydrogen Production and Storage – Managing liquid hydrogen in energy and aeros ...

Read More

A forged steel trunnion mounted ball valve is a heavy-duty valve designed for reliable shutoff and control in high-pressure, high-temperature, and demanding process conditions. Unlike floating ball designs, the ball in a trunnion-mounted configuration is supported at both the top and bottom, reducing operating torque and minimizing seat wear. The use of forged steel enhances mechanical strength, structural integrity, and resistance to pressure-induced deformation, making these valves ideal for critical applications in the oil & gas, petrochemical, power generation, and industrial sectors. Typical Operating Conditions Forged steel trunnion mounted ball valves are commonly used in: High-Pressure Pipelines – Transporting crude oil, natural gas, refined products, and chemical fluids. Offshore and Subsea Systems – Handling extreme pressure, corrosive seawater exposure, and space-limited environments. Refineries and Petrochemical Plants – Isolating and controlling process fluids in hydrocracking, reforming, and catalytic units. Power Plants – Managing high-temperature steam and cooling water systems. ...

Read More

Trunnion Mounted Full Welded Ball Valve – Technical Overview A trunnion mounted full welded ball valve is a high-performance pipeline valve designed for long-term, maintenance-free service in high-pressure and large-diameter applications. The full welded body construction eliminates body joints and bolting, ensuring zero external leakage, improved structural strength, and enhanced resistance to pipeline stresses. In a trunnion mounted design, the ball is supported at both the top and bottom by trunnion bearings, significantly reducing operating torque and enabling smooth operation under high differential pressures. This makes it an ideal solution for oil & gas transmission, natural gas distribution, petrochemical processing, and buried pipeline systems . Key Operating Environments Long-Distance Natural Gas Pipelines – Minimizes leakage risk and maintenance in remote areas. Oil & Gas Gathering and Transmission Systems – Handles high pressure and large flow rates with ease. Underground and Subsea Pipelines – Fully welded construction resists corrosion and environmental impact. Refineries and Petrochem ...

Read More

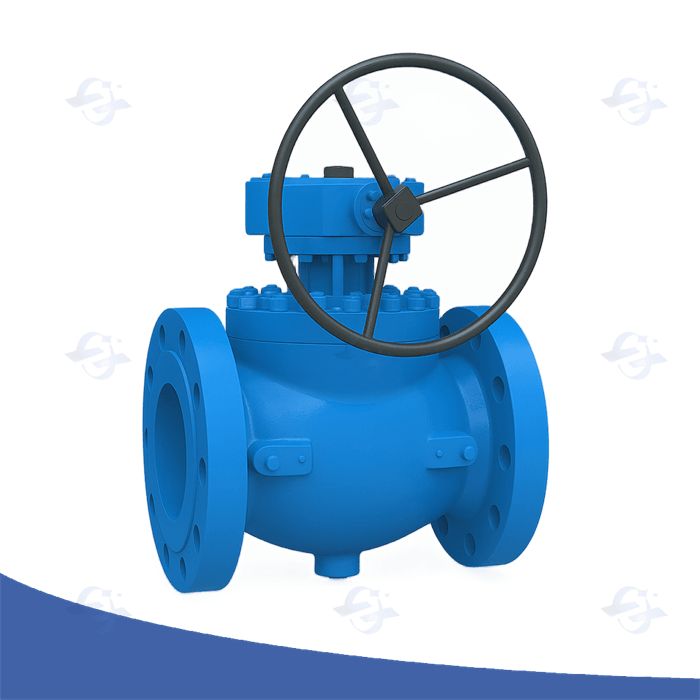

Trunnion Mounted Top Entry Ball Valve – Detailed Overview A trunnion mounted top entry ball valve is a high-reliability valve designed for critical applications in oil & gas, petrochemical, power generation, and industrial processes. The top entry design allows maintenance and inspection of internal components without removing the valve from the pipeline, minimizing downtime and operational costs. The trunnion-mounted configuration supports the ball with fixed bearings at the top and bottom, reducing operating torque and enhancing sealing reliability, especially in high-pressure and large-diameter systems. Typical Applications and Operating Conditions Oil & Gas Pipelines and Processing Facilities – For secure isolation and flow control in upstream, midstream, and downstream systems. Petrochemical Plants – Handling aggressive chemicals, high temperatures, and pressures. Power Plants – Managing steam, feedwater, and cooling circuits with reliable shutoff. Refineries – Used in cracking units, catalytic reformers, and fractionation towers. Water Treatment and Industrial Processes – F ...

Read More

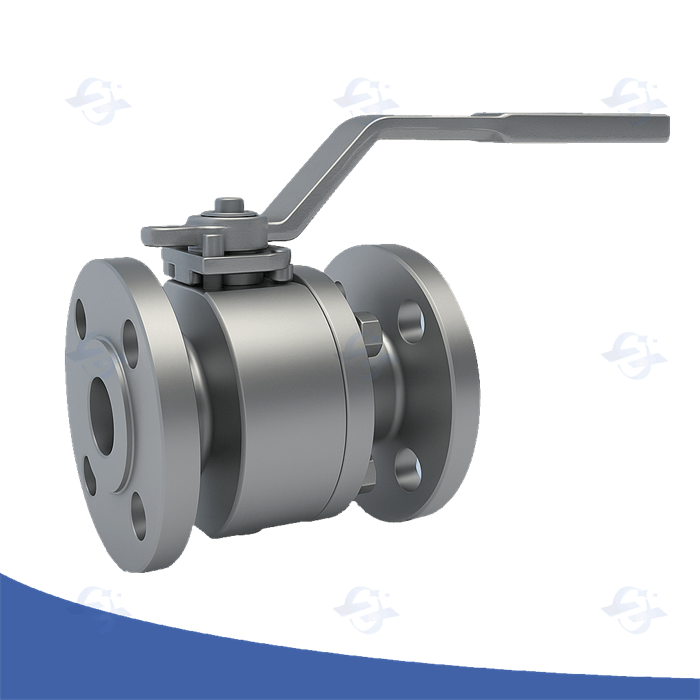

Floating Ball Valve – Comprehensive Overview A floating ball valve is a widely used quarter-turn valve that uses a free-floating ball inside the valve body to provide reliable shutoff and flow control. Unlike trunnion mounted designs, the ball is held in place only by the valve seats and is free to move slightly downstream under pressure, which helps press the ball firmly against the downstream seat to achieve a tight seal. Working Principle and Design In a floating ball valve, the ball is not fixed to the stem; instead, the stem rotates the ball to open or close the valve. When the valve is closed, process pressure pushes the ball against the downstream seat, enhancing the seal. This design is simple, cost-effective, and ideal for small to medium-sized valves where torque requirements are manageable. Typical Applications and Operating Conditions Oil & Gas Pipelines – Suitable for upstream and midstream applications with moderate pressure ratings. Chemical and Petrochemical Processing – Handling a variety of fluids including corrosive and non-corrosive media. Water Treatment and Utilities – Used in clean water and wa ...

Read More

Double Block and Bleed Valve (DBB Valve) – Comprehensive Overview A Double Block and Bleed Valve is a specialized isolation valve designed to provide two independent sealing barriers and an intermediate cavity bleed within a single, compact assembly. This configuration allows operators to isolate a section of the pipeline, drain the trapped medium between the seals, and verify zero leakage before performing maintenance or testing. By combining these functions into one body, DBB valves minimize space usage, reduce weight, and lower potential leak points compared to conventional multi-valve setups. Typical Operating Conditions DBB valves are widely used in critical process environments where safety, leak prevention, and operational efficiency are paramount: Oil & Gas Pipelines – Ensuring secure isolation during pigging operations, meter calibration, and section maintenance. Offshore Platforms – Handling high pressures, corrosive seawater exposure, and limited installation space. Petrochemical Plants – Isolating hazardous fluids in refining, cracking, and distillation units. Power Generati ...

Read More

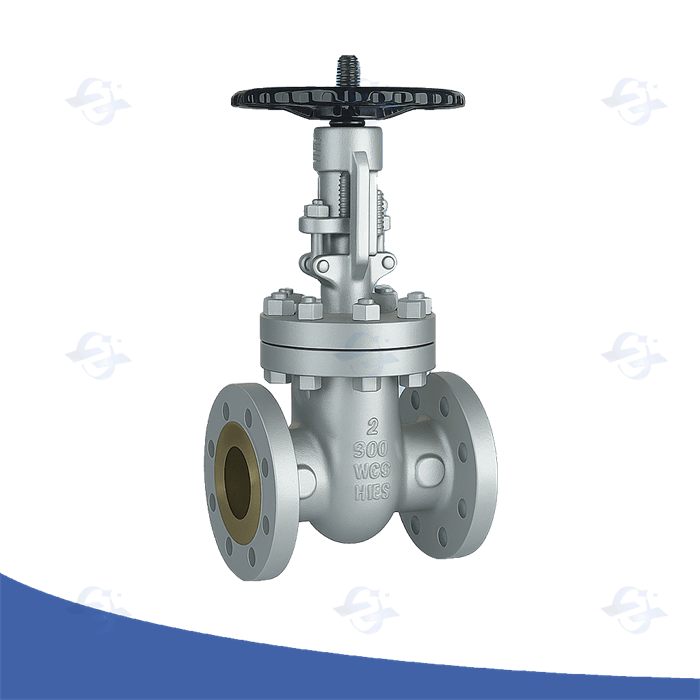

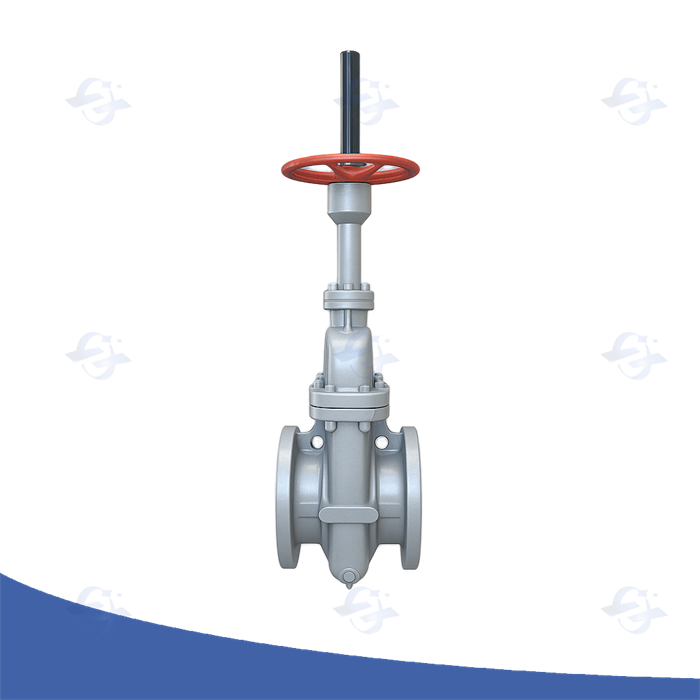

API Standard Cast Steel Gate Valve – Comprehensive Overview An API standard cast steel gate valve is a vital component in pipeline systems designed to provide reliable isolation and minimal pressure drop across a wide range of industrial applications. Built to comply with API (American Petroleum Institute) standards , these valves ensure consistency in design, materials, and performance, meeting the stringent requirements of the oil, gas, petrochemical, and power generation industries. Material and Construction Cast Steel Body (WCB, WCC, LCB, LCC) – Offers high mechanical strength, durability, and excellent resistance to pressure and temperature fluctuations. Trim Materials – Commonly include stainless steel, alloy steels, or hardened metals to ensure longevity and corrosion resistance of the seating surfaces. Bolted Bonnet Design – Facilitates easier maintenance and inspection. Cast steel manufacturing enables cost-effective production of large valves with reliable mechanical integrity, making them suitable for demanding pipeline services. Applications and Typical Operating Conditions Oil & ...

Read More

API Standard Bevel Gear Gate Valve – Comprehensive Overview An API standard bevel gear gate valve is engineered to provide precise flow control and reliable isolation in large-diameter, high-pressure pipeline systems. Designed according to stringent API (American Petroleum Institute) standards , these valves are equipped with a bevel gear mechanism to facilitate easier operation of heavy-duty gates, especially in high torque applications where manual operation would otherwise be challenging. Key Features and Design Bevel Gear Actuation : The integrated bevel gear mechanism reduces the effort required to operate the valve, enabling smooth and controlled opening and closing of the gate, particularly beneficial for valves of large sizes or in high-pressure service. Cast Steel Construction : Typically manufactured with cast steel bodies (such as WCB or WCC grades), these valves combine mechanical strength with cost-effective production, suitable for demanding industrial environments. Standard Compliance : Built to meet API 600 and API 6D standards, ensuring consistent dimensions, pressure ratings (ranging from Class 150 to Class 2500), and performa ...

Read More

API Standard Cast Steel Gate Valve – Comprehensive Overview An API standard cast steel gate valve is a vital component in pipeline systems designed to provide reliable isolation and minimal pressure drop across a wide range of industrial applications. Built to comply with API (American Petroleum Institute) standards , these valves ensure consistency in design, materials, and performance, meeting the stringent requirements of the oil, gas, petrochemical, and power generation industries. Material and Construction Cast Steel Body (WCB, WCC, LCB, LCC) – Offers high mechanical strength, durability, and excellent resistance to pressure and temperature fluctuations. Trim Materials – Commonly include stainless steel, alloy steels, or hardened metals to ensure longevity and corrosion resistance of the seating surfaces. Bolted Bonnet Design – Facilitates easier maintenance and inspection. Cast steel manufacturing enables cost-effective production of large valves with reliable mechanical integrity, making them suitable for demanding pipeline services. Applications and Typical Operating Conditions Oil & ...

Read More

API Standard Cast Steel Gate Valve – Comprehensive Overview An API standard cast steel gate valve is a vital component in pipeline systems designed to provide reliable isolation and minimal pressure drop across a wide range of industrial applications. Built to comply with API (American Petroleum Institute) standards , these valves ensure consistency in design, materials, and performance, meeting the stringent requirements of the oil, gas, petrochemical, and power generation industries. Material and Construction Cast Steel Body (WCB, WCC, LCB, LCC) – Offers high mechanical strength, durability, and excellent resistance to pressure and temperature fluctuations. Trim Materials – Commonly include stainless steel, alloy steels, or hardened metals to ensure longevity and corrosion resistance of the seating surfaces. Bolted Bonnet Design – Facilitates easier maintenance and inspection. Cast steel manufacturing enables cost-effective production of large valves with reliable mechanical integrity, making them suitable for demanding pipeline services. Applications and Typical Operating Conditions Oil & ...

Read More

Flat Gate Valve with Diversion Hole – Detailed Overview A flat gate valve with diversion hole is a specialized valve designed to provide reliable flow control and isolation in pipeline systems where pressure equalization and smooth flow transition are essential. The unique feature of a diversion hole (or pressure equalizing hole) in the gate allows for gradual pressure balancing during valve operation, reducing hydraulic shock and minimizing wear on the valve components. Design and Working Principle Flat Gate Design : Unlike wedge or parallel gates, the flat gate provides a simple, sturdy barrier for fluid shutoff, offering a straightforward sealing surface. Diversion Hole Functionality : The incorporated hole in the gate facilitates pressure equalization between the upstream and downstream sides when the valve is partially open or during operation, preventing sudden pressure surges and reducing the risk of water hammer or pipeline stress. Body and Material : Commonly manufactured from cast steel (such as WCB or WCC), stainless steel, or alloy materials to withstand diverse industrial conditions including high pressure and corrosive media. ...

Read More

Flat Gate Valve – Overview A flat gate valve is a type of valve designed to provide efficient flow control by using a flat gate or disc to start or stop fluid flow. Its simple design ensures a full bore, minimal pressure drop, and reliable shut-off, making it suitable for a wide range of industrial piping systems. Key Features Flat Gate Design Uses a flat, rectangular gate that moves perpendicular to the flow path to block or allow fluid passage. Full Bore When fully open, the valve offers unobstructed flow, reducing turbulence and pressure loss. Robust Construction Manufactured from cast or forged steel with precision machining for durability and tight sealing. Connection Types Available in flanged, threaded, or welded ends to fit various pipeline configurations. Applications Ideal for oil & gas, petrochemical, power generation, and water treatment industries. Used in pipelines requiring reliable shut-off with minimal flow resistance. Suitable for on/off service in high-pressure and high-temperature environments. ...

Read More

Forged Steel Female Thread, Socket Welding Gate Valve – Comprehensive Overview A forged steel female thread, socket welding gate valve is a compact and robust valve designed for reliable flow isolation in piping systems where threaded and socket welding connections are preferred. Combining the strength of forged steel construction with versatile end connections, this valve is ideal for critical industrial applications requiring leak-tight performance and easy installation. Key Features and Construction Forged Steel Body : Manufactured through forging, the valve body offers superior mechanical strength, impact resistance, and high pressure-temperature ratings compared to cast steel counterparts. This makes it suitable for demanding environments including high-pressure and high-temperature services. Female Thread End Connection : One end of the valve features a female threaded connection, allowing quick and secure assembly with threaded pipes or fittings, often used in smaller piping systems or where disassembly may be required. Socket Welding End Connection : The opposite end utilizes a socket weld joint, which provides a strong, leak-proof perma ...

Read More

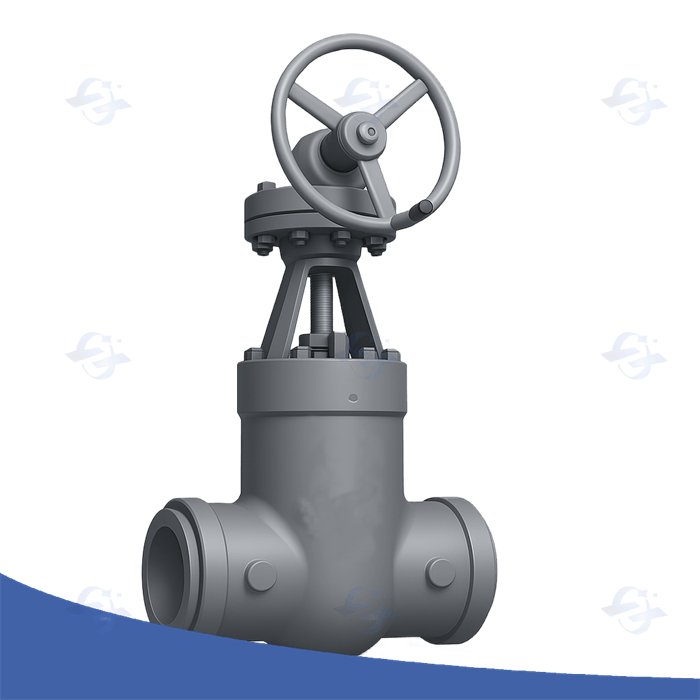

High Temperature and High Pressure Self-Sealing Gate Valve – Detailed Overview A high temperature and high pressure self-sealing gate valve is engineered to provide dependable isolation in challenging environments where both extreme heat and elevated pressure are present. Featuring advanced self-sealing technology , this valve ensures tight shutoff even under severe operating conditions, minimizing leakage risks and maintenance needs. Design Features and Working Principle Self-Sealing Mechanism : The valve employs a design where increased pressure enhances the sealing force between the gate and the seats, creating a tighter seal as operating pressure rises. This dynamic sealing action helps maintain integrity under fluctuating or high-pressure conditions. Robust Construction : Typically constructed from high-grade alloy steels or stainless steel, the valve body and gate components withstand thermal expansion, mechanical stress, and corrosive media found in demanding industrial processes. High-Temperature Resilience : Materials and packing are specially selected to maintain sealing performance and mechanical stability at temperatures that may ex ...

Read More

API Standard Flanged Globe Valve – Comprehensive Overview An API standard flanged globe valve is a crucial component in fluid control systems, designed to provide precise throttling and reliable shutoff in various industrial applications. Manufactured to meet API (American Petroleum Institute) standards , these valves ensure consistent quality, durability, and performance, particularly in oil & gas, petrochemical, power generation, and water treatment industries. Construction and Material Flanged End Connections : Designed according to ASME B16.5 standards, the flanged ends facilitate secure, leak-proof connections to piping systems, enabling easy installation and maintenance. Robust Body Materials : Typically constructed from cast steel (WCB, WCC), stainless steel, or alloy steels, offering excellent mechanical strength and corrosion resistance across a range of service conditions. Trim Components : Equipped with durable seating surfaces, often stainless steel or hardened alloys, to ensure tight shutoff and long service life. Bonnet Types : Bolted bonnet or pressure-seal bonnet options are available depending on pres ...

Read More

Forged Steel Cryogenic Globe Valve – Comprehensive Overview A forged steel cryogenic globe valve is engineered to provide precise flow control and reliable shutoff in extremely low-temperature environments, typically found in liquefied gas applications. Combining the strength of forged steel with specialized cryogenic design features, this valve ensures safe, leak-tight performance in critical processes involving LNG, liquid nitrogen, oxygen, and other cryogenic fluids. Key Features and Construction Forged Steel Body : Manufactured through forging, the valve body offers superior mechanical strength, toughness, and resistance to thermal shock compared to cast valves, making it ideal for cryogenic service. Cryogenic Design : Equipped with extended stems and special packing materials to prevent heat transfer and maintain seal integrity at temperatures as low as -196°C (-321°F). Globe Valve Configuration : Provides excellent throttling control with linear motion of the disk, allowing precise regulation of flow in cryogenic pipelines. Flanged or Butt Weld Ends : Common end connections to ensure secure, leak-proof installation i ...

Read More