Ash Discharge Ball Valve vs API 6D Ball Valve: Which Is Suitable for Fly Ash Systems?

Introduction

In fly ash and ash handling systems, valve selection is often underestimated during the early design stage.

However, in actual operation, using an unsuitable valve type frequently leads to blockage, excessive wear, and unplanned shutdowns.

In many power plant and industrial projects, standard API 6D ball valves are sometimes applied to ash discharge service simply because they are readily available or already approved for pipeline use. Based on project experience, this often results in valve jamming or sealing failure after only a few months of operation.

This article explains the real working conditions of fly ash systems, the design logic behind ash discharge ball valves, and provides a practical comparison with API 6D ball valves from an engineering perspective.

Typical Working Conditions in Fly Ash and Ash Handling Systems

Fly ash systems operate under conditions that are significantly harsher than normal pipeline services.

In real projects, the following conditions are commonly observed:

-

Highly abrasive media, such as fly ash and bottom ash

-

High solid concentration, often transported by air or water

-

Continuous erosion caused by high flow velocity

-

Frequent open–close cycles, especially during discharge and isolation

-

Medium to high operating temperatures, depending on boiler design

During commissioning or early operation, these factors often become evident when valves start showing increased operating torque or incomplete closing.

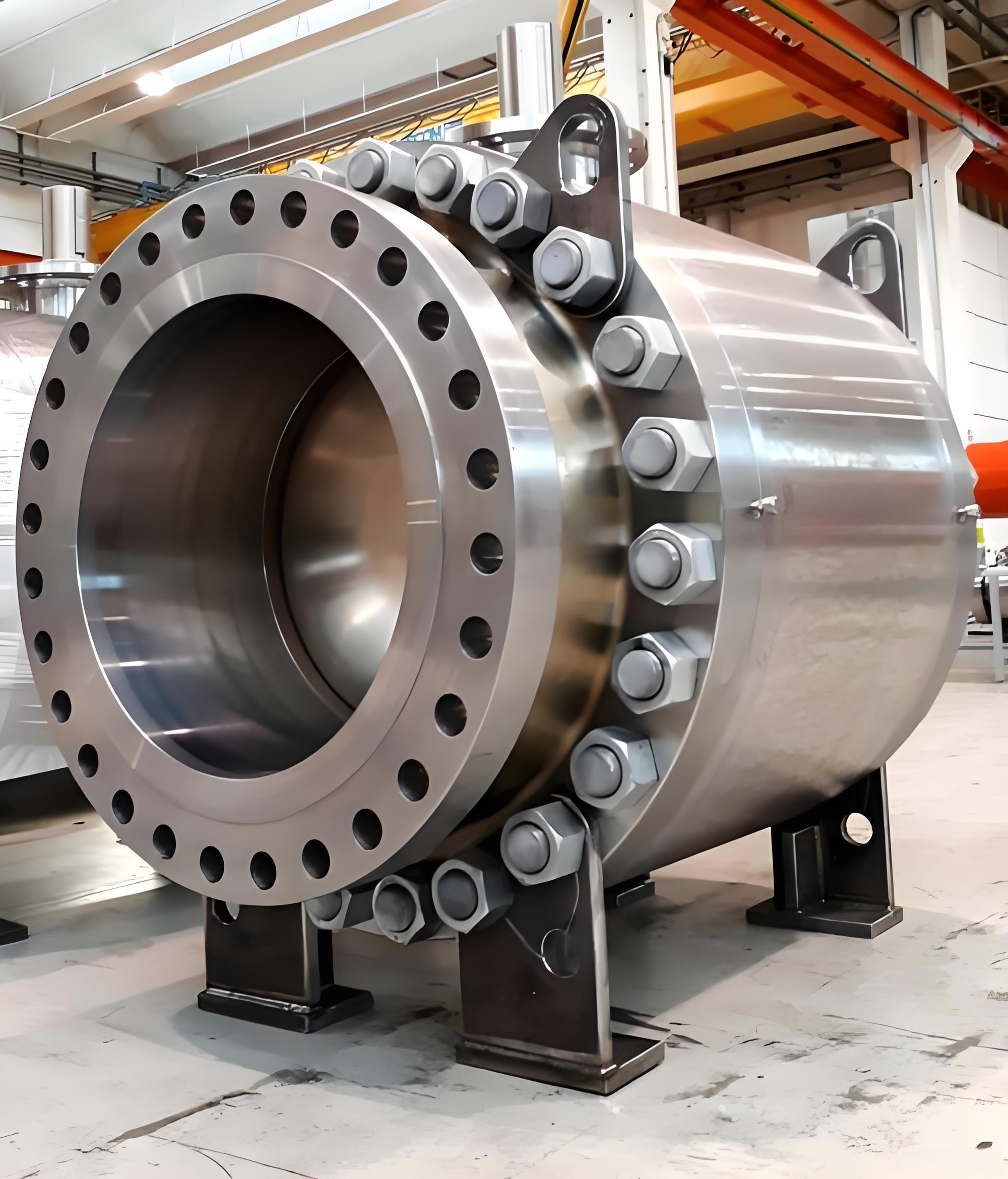

What Is an Ash Discharge Ball Valve?

An ash discharge ball valve is specifically designed for controlling abrasive and solid-laden media in ash handling systems.

Unlike standard pipeline ball valves, ash discharge ball valves are developed with a clear focus on wear resistance and anti-blocking performance, rather than achieving bubble-tight shutoff.

Typical Design Features

Based on common industrial designs, ash discharge ball valves usually include:

-

Metal-to-metal seating to withstand continuous abrasion

-

Reinforced valve body, providing longer service life under erosion

-

Full-bore or enlarged flow path, reducing ash buildup

-

Self-cleaning or scraping ball design, minimizing particle accumulation

-

Pneumatic actuation, suitable for high-frequency and automated operation

These design features are critical for maintaining stable operation in fly ash service over extended periods.

What Is an API 6D Ball Valve?

An API 6D ball valve is a pipeline valve primarily intended for oil, gas, and liquid transmission systems.

From an engineering standpoint, API 6D emphasizes:

-

Pressure containment and structural integrity

-

Fire-safe design requirements

-

Tight shut-off performance

-

Compatibility with long-distance pipelines

API 6D ball valves perform very well in clean or mildly contaminated media, where operating frequency is low and leakage requirements are strict.

Ash Discharge Ball Valve vs API 6D Ball Valve

Although both valve types share the ball valve principle, their design objectives and operating assumptions are completely different.

| Item | Ash Discharge Ball Valve | API 6D Ball Valve |

|---|---|---|

| Primary application | Fly ash & solid handling | Oil & gas pipelines |

| Typical media | Abrasive, solid-laden | Clean fluids |

| Seat design | Metal-to-metal | Soft or soft + metal |

| Wear resistance | High | Limited |

| Operating frequency | High | Low |

| Anti-blocking design | Yes | No |

| Leakage requirement | Process-grade | Tight shut-off |

| Design standard | Project-specific | API 6D |

From practical experience, problems usually occur when pipeline-type valves are forced into ash service, not the other way around.

Why API 6D Ball Valves Often Fail in Fly Ash Service

In actual plant operation, API 6D ball valves face several challenges in fly ash systems:

-

Seat erosion caused by continuous contact with ash particles

-

Ash accumulation in the valve cavity, especially after partial opening

-

Rapid increase in operating torque, noticeable during routine operation

-

Incomplete closing or sticking, often discovered during maintenance shutdowns

These issues are not related to manufacturing quality but to application mismatch. API 6D ball valves are simply not designed to handle heavy solid content and high-frequency operation.

How to Select the Right Valve for Ash Handling Systems

When selecting valves for fly ash or bottom ash service, engineers should focus on operating conditions rather than standards alone.

Key selection factors include:

-

Abrasiveness and particle size of the ash

-

Required operating frequency

-

System temperature and pressure

-

Maintenance accessibility and expected service life

For systems involving continuous abrasion and frequent operation, ash discharge ball valves with metal seats and anti-blocking design are generally the most reliable choice.

Conclusion

From an engineering perspective, fly ash service requires valves designed specifically for abrasive conditions.

While API 6D ball valves remain the preferred solution for pipeline isolation in oil and gas applications, ash discharge ball valves offer significantly better reliability and service life in ash handling systems.

Correct valve selection at the design stage can effectively reduce maintenance costs, operational risks, and unplanned downtime.

Engineering Support

If you are evaluating valves for fly ash or bottom ash handling projects, our engineering team can provide technical support and application-based recommendations based on actual operating conditions. Contact us.