Valve Appearance Inspection Standards

1. Introduction

Before delivery or installation, industrial valves must undergo appearance inspection to ensure that they are free from visible defects, contamination, or damages that could affect performance. Appearance inspection is a fundamental part of valve quality control, usually carried out alongside dimensional, pressure, and functional tests.

2. General Requirements

-

Surface Finish

-

The surface should be clean, smooth, and free from oil, rust, welding slag, or scale.

-

Coated or painted surfaces should be uniform, without blistering, peeling, or obvious color difference.

-

-

Casting and Forging Quality

-

No cracks, shrinkage cavities, sand holes, or other casting defects.

-

No sharp edges or burrs on machined surfaces.

-

-

Welding Areas

-

Weld seams should be smooth, even, and free from cracks, pores, or undercuts.

-

Weld spatter should be removed, and grinding should not affect wall thickness.

-

-

Markings

-

Valve body markings (manufacturer’s logo, size, pressure rating, material, flow direction, standard) should be clear, correct, and permanent.

-

Arrows indicating flow direction must be visible.

-

-

Connections

-

Flanges: No radial cracks, dents, or uneven surfaces; bolt holes should be smooth and aligned.

-

Threads: Should be clean, without damage, burrs, or deformation.

-

Socket weld and butt weld ends: Machined smoothly with correct bevel angle.

-

-

Accessories and Assembly

-

Bolts, nuts, and fasteners should be tight and free from corrosion.

-

Handles, actuators, and gearboxes should be firmly attached and flexible to operate.

-

Nameplates should be intact, firmly fixed, and readable.

-

3. Inspection Criteria (Visual & Dimensional)

-

Visual inspection: Carried out under sufficient lighting with the naked eye or magnifying glass.

-

Dimensional inspection: Measured with calipers, micrometers, or gauges, according to design drawings and relevant standards (API, ASME, ISO, GB).

-

Surface coating thickness: Measured with a coating thickness gauge to ensure compliance with requirements.

4. Illustrations (Typical Examples)

-

Acceptable valve surface: smooth paint, clear markings, no visible damage.

-

Defective surface: rust spots, paint peeling, dents, casting pores.

-

Proper flange face: flat, concentric bolt holes, smooth sealing surface.

-

Damaged flange face: scratches, cracks, or pitting.

5. Conclusion

Appearance inspection ensures that valves meet quality standards before shipment and installation. By checking surfaces, markings, connections, and coatings, manufacturers and users can prevent failures caused by hidden defects and extend the valve’s service life.

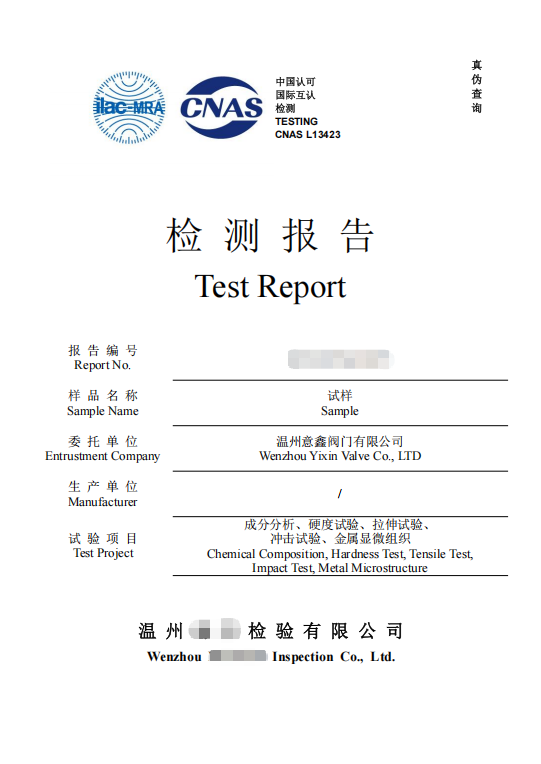

YIXIN strictly follows international standards (API, ASME, ISO) and conducts 100% appearance inspection on all valves to guarantee reliable performance for industrial applications.