High-Pressure Valve Maintenance and Care Tips

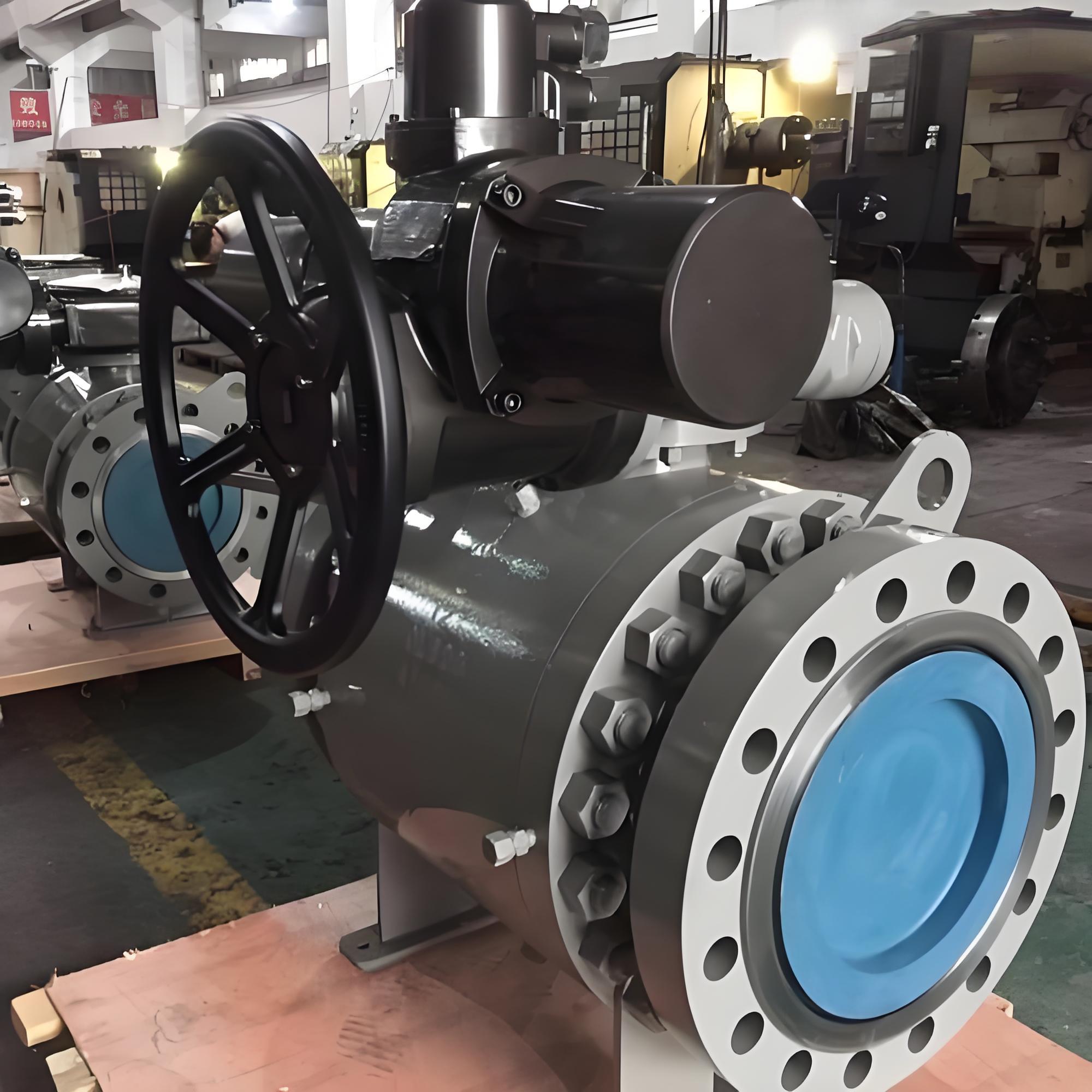

High-pressure valves play a critical role in oil & gas, power generation, petrochemical, and industrial piping systems. They are designed to withstand extreme pressure, temperature, and corrosive media, making proper maintenance essential for safety and long service life.

Neglecting maintenance can lead to leakage, equipment downtime, costly repairs, and safety risks. This article provides a comprehensive guide on high-pressure valve maintenance and care tips, helping engineers and operators ensure reliable valve performance.

1. Importance of Maintaining High-Pressure Valves

-

Safety: Prevents catastrophic failures in high-pressure pipelines.

-

Efficiency: Ensures valves operate smoothly with minimal energy loss.

-

Longevity: Extends the service life of valves, reducing replacement costs.

-

Compliance: Meets industry standards such as API, ASME, and ISO requirements.

2. Routine Inspection Checklist

✅ Visual Inspection

-

Look for external leaks, cracks, or corrosion on the valve body and connections.

-

Check flange gaskets, bolts, and weld joints.

✅ Operational Check

-

Verify smooth opening and closing without unusual resistance.

-

Listen for abnormal noises (indicating internal damage or cavitation).

✅ Pressure & Temperature Monitoring

-

Confirm valve operation within rated pressure–temperature limits.

-

Record deviations for predictive maintenance.

3. Lubrication and Sealing Maintenance

-

Stem and Bearings: Apply appropriate lubricants to reduce friction and prevent seizure.

-

Sealing Surfaces: For ball and plug valves, use compatible valve grease to ensure tight sealing.

-

Packing Adjustment: Check gland packing regularly; tighten or replace if leakage occurs.

⚠️ Always use lubricants and sealing compounds that are compatible with process fluids and pressure ratings.

4. Cleaning and Preventive Care

-

Internal Cleaning: Flush the valve periodically to remove scale, sediment, or debris.

-

External Protection: Apply anti-corrosion coatings or covers in offshore or corrosive environments.

-

Actuator Care: Inspect pneumatic/electric actuators for air leaks, wiring issues, or calibration errors.

5. Common Maintenance Issues in High-Pressure Valves

-

Seat Wear → Causes internal leakage; replace or re-lap seats.

-

Stem Packing Leakage → Retighten gland or replace packing rings.

-

Corrosion and Erosion → Use corrosion-resistant alloys or coatings.

-

Sticking or Hard Operation → Indicates buildup, misalignment, or actuator failure.

6. Safety Precautions During Maintenance

⚠️ Always follow Lockout-Tagout (LOTO) procedures before valve maintenance.

⚠️ Depressurize and drain the pipeline before disassembly.

⚠️ Wear proper PPE (gloves, face shields, safety boots).

⚠️ Never use excessive force to operate a stuck valve—identify the cause first.

7. Best Practices for Long-Term Reliability

-

Implement a predictive maintenance program using vibration, pressure, and temperature monitoring.

-

Maintain a spare parts inventory (seats, gaskets, packing) for quick replacement.

-

Schedule periodic hydrostatic testing to verify valve pressure integrity.

-

Train operators in valve handling and emergency shutdown procedures.

8. Conclusion

High-pressure valves are mission-critical components in industrial systems. Proper inspection, lubrication, cleaning, and timely replacement of wear parts ensure safe and efficient operation. By following these maintenance tips and adhering to industry standards, plant operators can significantly reduce downtime, avoid costly failures, and enhance safety.

FAQ: High-Pressure Valve Maintenance

Q1: How often should high-pressure valves be inspected?

Routine visual inspections should be conducted monthly, with detailed maintenance every 6–12 months, depending on service conditions.

Q2: What lubricant should be used for high-pressure ball or plug valves?

Always use valve-specific greases designed for high-pressure and compatible with the process fluid (e.g., hydrocarbon or steam service).

Q3: Can high-pressure valves be repaired on-site?

Yes, many repairs such as packing replacement or seat re-lapping can be done on-site, but severe damage may require factory refurbishment.

Q4: What are the signs that a valve needs urgent maintenance?

-

Difficulty in operation

-

External or internal leakage

-

Unusual vibration or noise

-

Sudden pressure drops across the valve

Q5: Which standards cover valve maintenance and testing?

Standards such as API 598 (testing), API 6D (pipeline valves), API 600/602 (gate valves), and ASME B16.34 provide guidelines for valve design, testing, and maintenance.