API 6FA Fire Test for Valves Explained: A Complete Guide

In industries such as oil & gas, petrochemical, and power generation, safety is paramount. Valves used in critical service must continue to perform even under fire conditions. To ensure this, the API 6FA fire test is one of the most widely recognized standards for qualifying fire-safe valves.

This article provides a comprehensive explanation of API 6FA, including its purpose, testing procedures, acceptance criteria, and its importance for end-users and EPC contractors.

What Is API 6FA?

API 6FA is the American Petroleum Institute’s Fire Test Standard for Valves.

-

First published in 1974 and regularly updated.

-

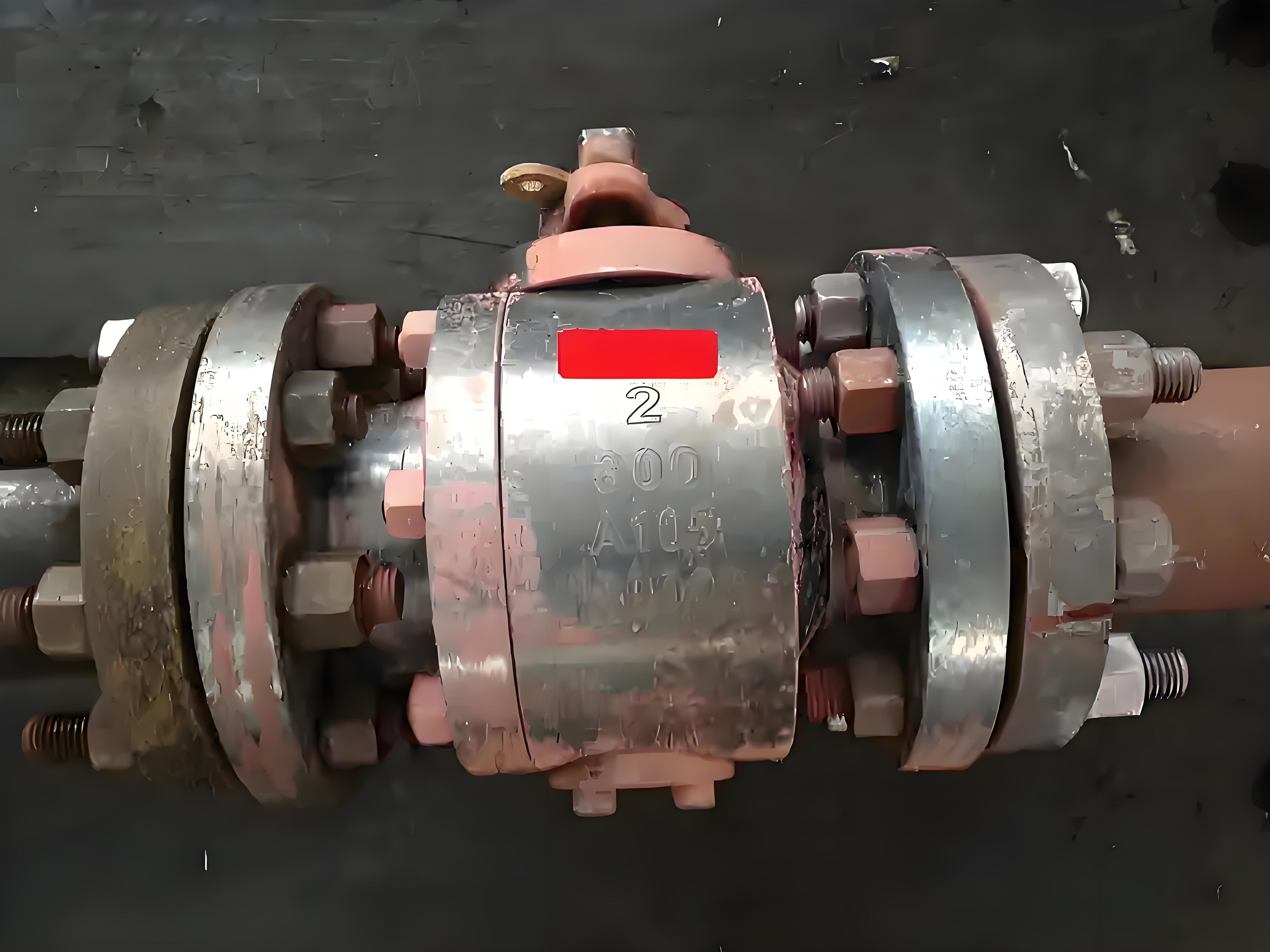

Specifies a fire test procedure for quarter-turn valves, check valves, and other types.

-

Ensures valves maintain sealing capability during and after fire exposure.

In simple terms, API 6FA verifies that a valve is fire-safe—meaning it can still isolate fluid and prevent leaks in the event of a fire.

Purpose of API 6FA Fire Test

The main objectives of the fire test are to confirm that a valve:

-

Minimizes external leakage during fire exposure.

-

Maintains internal sealing between upstream and downstream sides.

-

Operates after fire (can be opened/closed after cooling).

-

Prevents environmental and personnel hazards by controlling flammable leaks.

API 6FA Fire Test Procedure

The standard fire test consists of three main phases:

1. Fire Exposure Phase

-

Valve is mounted on a test rig and pressurized with water or gas.

-

Burners apply fire to the valve at 750–1000 °C (1382–1832 °F).

-

Exposure time: typically 30 minutes.

-

Valve must withstand the direct flame while under pressure.

2. Cooling Phase

-

After fire exposure, water is sprayed to cool the valve rapidly.

-

This simulates firefighting conditions.

-

Valve is still pressurized to monitor sealing performance.

3. Operational Phase

-

After cooling, the valve is operated (opened/closed).

-

Functionality must remain intact, ensuring continued operation in emergency conditions.

Acceptance Criteria of API 6FA

A valve passes the API 6FA test if it meets the following conditions:

-

External Leakage

-

Minimal leakage allowed during and after fire.

-

Typically measured by liters per minute (L/min) or equivalent standard limits.

-

-

Through Leakage (Seat Leakage)

-

Internal leakage between upstream and downstream sides must remain within limits.

-

-

Operational Capability

-

Valve must be operable after fire and cooling.

-

Torque or actuation force must not exceed design limits.

-

-

No Stem Blowout or Catastrophic Failure

-

The stem and body must remain intact without dangerous ejection or breakage.

-

Common Design Features for Fire-Safe Valves

Manufacturers often incorporate specific design elements to meet API 6FA:

-

Secondary metal-to-metal seat to ensure sealing if soft seats are destroyed.

-

Fire-safe stem seals with graphite packing instead of elastomers.

-

Anti-blowout stem design to prevent stem ejection.

-

High-temperature resistant body gaskets.

API 6FA vs. Other Fire Test Standards

-

API 6FA – Valve fire test standard, widely used in oil & gas projects.

-

API 607 – Fire test for soft-seated quarter-turn valves.

-

ISO 10497 – International fire test standard, similar to API 607.

-

BS 6755 Part 2 – Older British fire test standard (still referenced in some regions).

Why API 6FA Certification Matters

For EPC contractors, oil majors, and end-users, valves with API 6FA certification provide:

-

Regulatory compliance in oil & gas projects.

-

Increased safety assurance during fire incidents.

-

Reduced liability for equipment failure.

-

Proof of quality from valve manufacturers.

Conclusion

The API 6FA fire test is a crucial qualification standard ensuring that valves remain leak-tight, operational, and safe even under fire exposure. For critical applications in oil & gas, petrochemical, and power plants, choosing valves that are API 6FA certified is not only a regulatory requirement but also a matter of safety and reliability.

When selecting valves for fire-prone environments, always ensure:

-

API 6FA compliance certificate is available.

-

Manufacturer provides test reports with leakage and operation results.

-

Design incorporates fire-safe features like metal-to-metal seats and graphite seals.

With proper certification and design, fire-safe valves can protect both facilities and lives.

FAQ – API 6FA Fire Test

Q1: Which valves require API 6FA fire testing?

Typically ball valves, gate valves, globe valves, and check valves used in hydrocarbon service.

Q2: How long does the fire exposure last in API 6FA?

Approximately 30 minutes at 750–1000 °C.

Q3: What is the difference between API 6FA and API 607?

API 6FA is broader (applies to multiple valve types), while API 607 focuses specifically on soft-seated quarter-turn valves.