Difference Between Manual Ball Valves and Pneumatic Ball Valves

When it comes to fluid control in industrial pipelines, ball valves are among the most widely used valve types. Known for their reliable sealing and simple operation, ball valves are available in different actuation methods. Two of the most common types are manual ball valves and pneumatic ball valves.

Although both share the same basic structure and working principle (using a rotating ball to open or shut the flow), their operation method, cost, speed, and applications differ significantly. Choosing the right one is crucial for efficiency, safety, and cost savings.

1. Operation Method

-

Manual Ball Valves

Operated by hand through a lever or gear handle. The operator rotates the handle 90° to open or close the valve.-

Simple and reliable

-

No external power required

-

Best for smaller systems or low-frequency operations

-

-

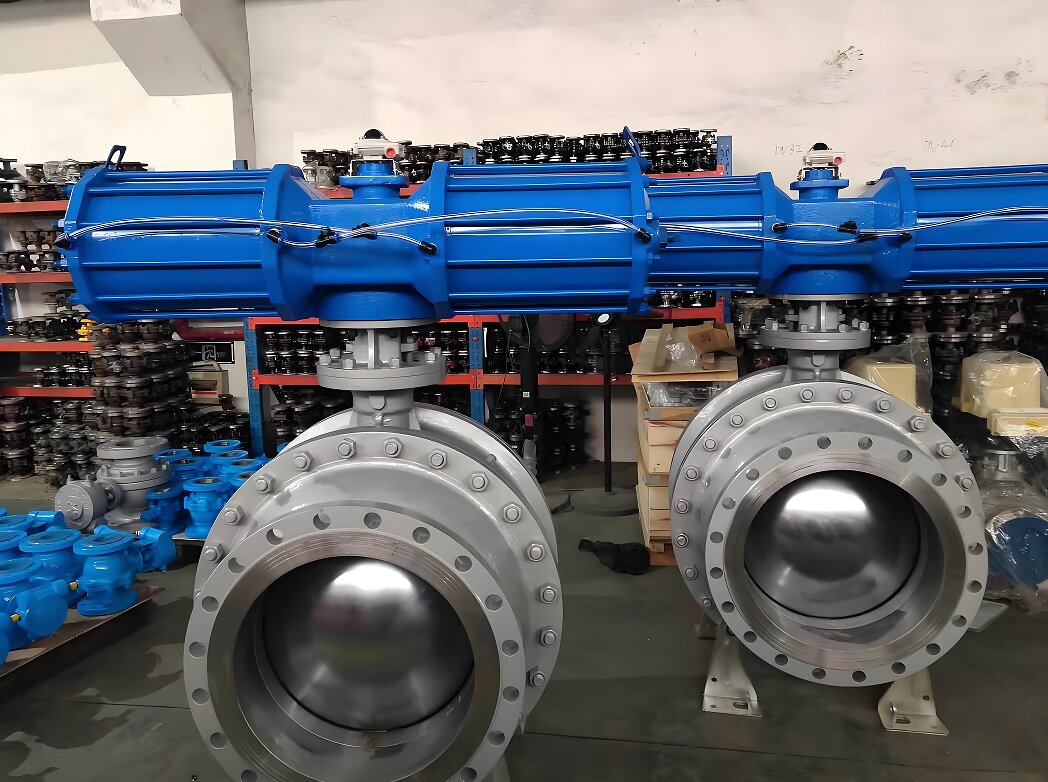

Pneumatic Ball Valves

Operated automatically using a pneumatic actuator powered by compressed air. The actuator rotates the ball quickly to control flow.-

Fast response, typically 1–2 seconds

-

Can be controlled remotely and integrated into automated systems

-

Requires a stable air supply

-

2. Control System

-

Manual Ball Valves: Only allow on-site manual operation.

-

Pneumatic Ball Valves: Can be combined with solenoid valves, limit switches, and PLC systems for remote and automatic control, making them suitable for modern automated industries.

3. Application Scenarios

-

Manual Ball Valves

-

Small pipeline diameters (DN ≤ 150 mm)

-

Systems with low operating frequency

-

Projects with limited budget

-

Typical industries: HVAC, water supply, fire protection, residential systems

-

-

Pneumatic Ball Valves

-

Large pipeline diameters (DN ≥ 200 mm) or high-frequency operation

-

Systems requiring emergency shut-off or automation

-

Industries with strict safety and efficiency requirements

-

Typical industries: oil & gas, petrochemical, pharmaceutical, food & beverage, natural gas transmission

-

4. Cost and Maintenance

-

Manual Ball Valves

-

Low cost

-

Easy installation and maintenance

-

No additional equipment required

-

-

Pneumatic Ball Valves

-

Higher initial cost (actuator, air supply, control devices)

-

Maintenance requires air system checks and actuator servicing

-

More complex but highly efficient in the long term

-

5. Switching Speed

-

Manual Ball Valves: Switching speed depends on the operator; larger valves may be harder to operate.

-

Pneumatic Ball Valves: Extremely fast, allowing emergency cut-off or rapid system response.

Manual vs Pneumatic Ball Valves – Comparison Table

| Feature | Manual Ball Valve | Pneumatic Ball Valve |

|---|---|---|

| Operation | Hand lever / gear | Compressed air actuator |

| Control | On-site only | Remote & automated |

| Switching Speed | Slow, manual | Very fast (1–2 sec) |

| Suitable Diameter | Small to medium | Medium to large |

| Cost | Low | Higher |

| Maintenance | Simple | Requires air system upkeep |

| Applications | HVAC, water, fire systems | Oil & gas, chemical, automated factories |

Which One Should You Choose?

-

Choose a manual ball valve if:

-

Your system has low operating frequency

-

You want a cost-effective solution

-

You are dealing with smaller pipelines

-

-

Choose a pneumatic ball valve if:

-

Your system requires automation or remote control

-

You need fast switching for safety reasons

-

You are managing large pipelines or critical industrial processes

Conclusion

Both manual ball valves and pneumatic ball valves play essential roles in industrial and commercial applications. The choice depends on your project’s budget, operating frequency, control requirements, and safety needs.

By understanding the differences, engineers and procurement managers can make smarter decisions that improve system efficiency, reliability, and cost-effectiveness.