Butterfly Valve Actuator Wiring Diagram Example: A Practical Guide

When installing or maintaining a butterfly valve with an actuator, one of the most critical steps is wiring the actuator correctly. Proper wiring ensures reliable valve operation, prevents electrical faults, and extends the service life of both the actuator and the valve. In this blog, we provide a practical overview of butterfly valve actuator wiring, including key components, a sample wiring diagram, and important installation tips.

1. Key Components in Actuator Wiring

Before looking at the wiring diagram, it’s important to understand the basic elements involved:

-

Power Supply – Typically 220V AC, 110V AC, or 24V DC depending on the actuator type.

-

Control Signal – On/Off (two-position) or Modulating (4-20mA, 0-10V).

-

Limit Switches – Indicate fully open or fully closed valve position.

-

Terminal Block – Connection point for power and signal wires.

-

Grounding – Essential for safety and protection against electrical surges.

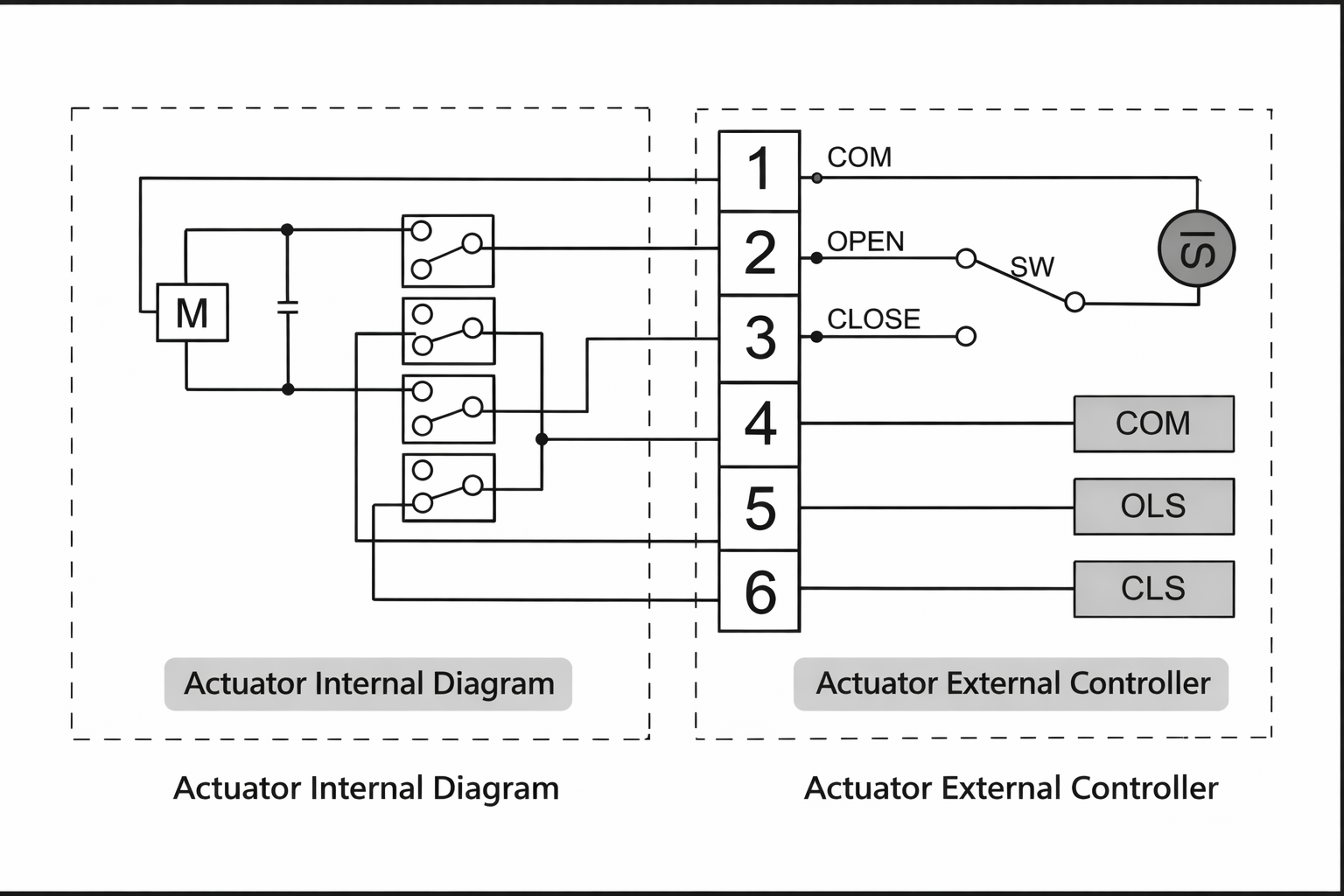

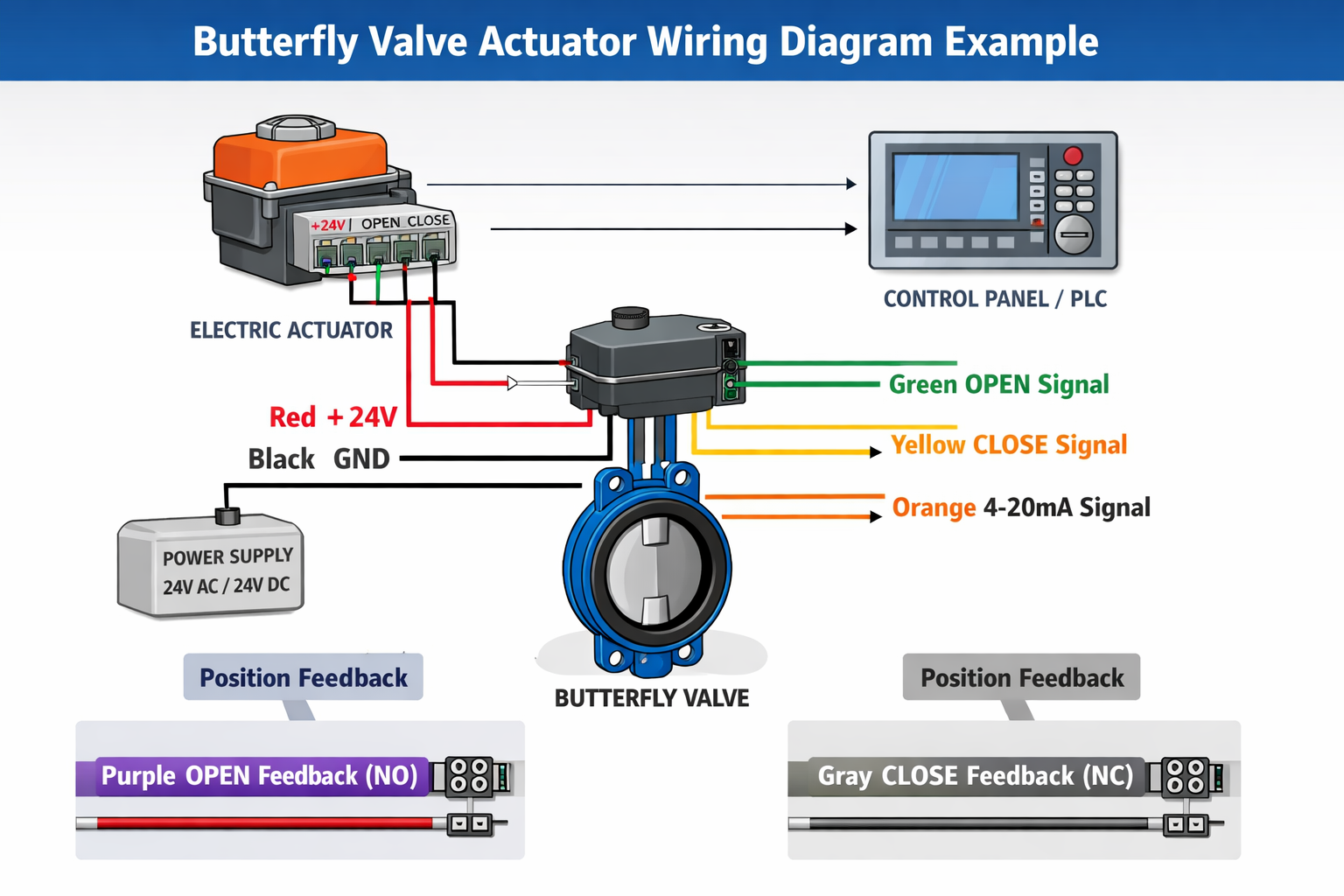

2. Sample Butterfly Valve Actuator Wiring Diagram

Below is a simplified example of a wiring diagram:

This is a general example; always check the actuator manufacturer’s manual for exact wiring details.

3. Installation Steps

-

Check voltage compatibility – Match actuator power rating with your supply.

-

Connect ground wire first – For safety and compliance with IEC standards.

-

Wire power terminals – L (Live) and N (Neutral) for AC actuators, or +/– for DC.

-

Connect control signal wires – Depending on whether On/Off or Modulating type.

-

Verify limit switch connections – Ensure open/close feedback signals are wired.

-

Test operation – Power up the actuator and confirm valve movement matches the control signal.

4. Safety & Best Practices

-

Always follow IEC/NEC electrical standards.

-

Use proper cable glands for waterproof protection (IP65/IP67 actuators).

-

Never energize the actuator before wiring is fully completed.

-

Keep control and power cables separated to reduce electrical interference.

-

Label wires for easier maintenance.

Conclusion

Understanding butterfly valve actuator wiring is essential for safe installation and reliable operation. Using the correct wiring diagram and following safety practices will prevent downtime and costly repairs. If you are unsure, always consult the actuator’s manual or a certified technician.