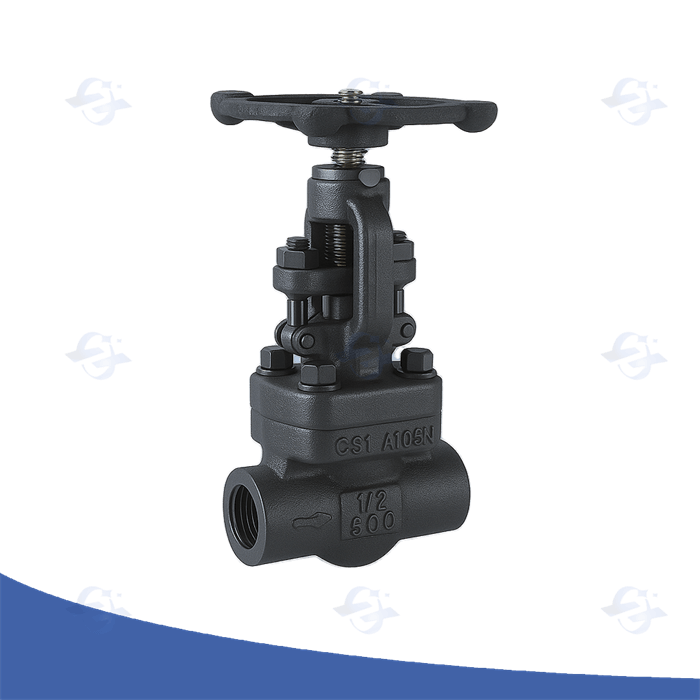

Forged Steel Female Thread, Socket Welding Globe Valve – Overview The forged steel female thread, socket welding globe valve is a robust valve designed for precise flow regulation and reliable shut-off in piping systems. Featuring forged steel construction, female threaded and socket welding ends, this valve combines strength with versatile connection options to suit demanding industrial environments. Key Features Forged Steel Body Ensures high mechanical strength, impact resistance, and durability under high pressure and temperature. Female Thread Connection Allows easy and secure installation with male-threaded pipes or fittings, facilitating maintenance and system flexibility. Socket Welding End Provides a reliable, leak-proof connection by welding the pipe into the valve socket, suitable for high-pressure applications. Globe Valve Design Offers precise throttling control with a linear motion disc and seat, ideal for flow regulation. Sealing and Trim Materials Options include stainless steel or alloy trims for enhanced corrosion resistance and extended service life. ...

Read More

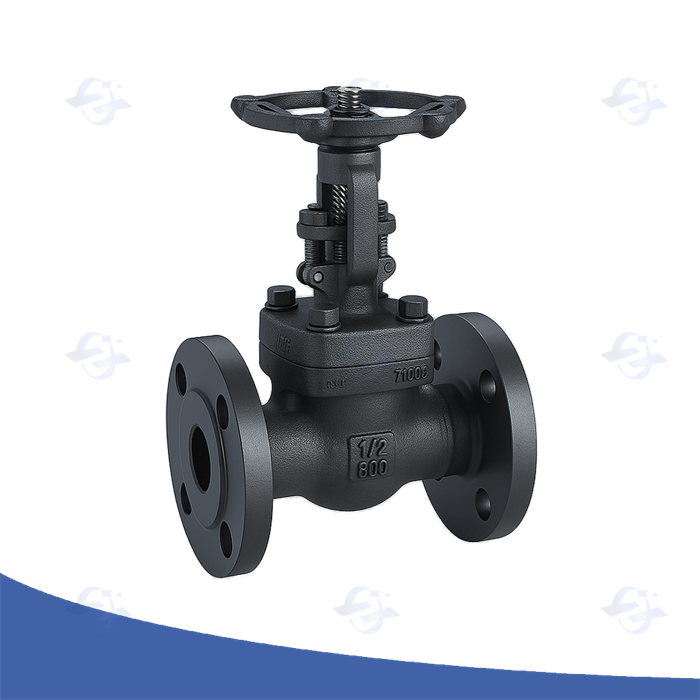

Forged Steel Flanged Globe Valve – Comprehensive Overview A forged steel flanged globe valve is a high-performance valve designed for precise flow control and reliable shutoff in industrial piping systems. Combining the strength and durability of forged steel construction with standardized flanged end connections, this valve is widely used in critical applications where safety, leak-tight performance, and easy maintenance are essential. Key Features and Construction Forged Steel Body : Manufactured through forging, the valve body offers superior mechanical strength, impact resistance, and excellent pressure-temperature ratings compared to cast valves, making it suitable for demanding service conditions. Flanged End Connections : Designed according to ASME B16.5 standards, flanged ends provide secure, leak-proof connections that facilitate installation, inspection, and maintenance in pipelines. Globe Valve Design : Utilizes a linear motion disc and seat configuration that allows precise throttling and effective isolation, making it ideal for regulating flow in complex process systems. Robust Trim Materials : Internal compon ...

Read More

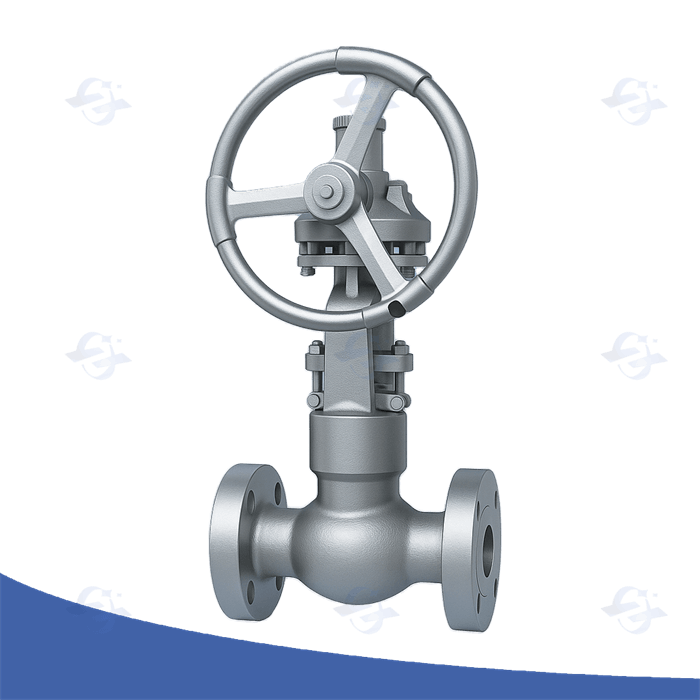

High Temperature and High Pressure Globe Valve – Comprehensive Overview A high temperature and high pressure globe valve is engineered to provide precise flow control and reliable shutoff in demanding industrial environments where both elevated temperatures and pressures are present. This valve type is essential for applications requiring robust construction, superior sealing performance, and long-term durability under severe operating conditions. Design and Construction Features Robust Body Materials : Typically made from alloy steels, stainless steels, or other high-performance materials capable of withstanding extreme heat and pressure without deformation or failure. Globe Valve Configuration : Employs a linear motion disk that moves perpendicular to the flow, enabling accurate throttling and effective sealing. Pressure-Temperature Ratings : Designed to comply with industry standards such as API 600 and ASME B16.34, supporting ANSI pressure classes up to 2500 and temperatures exceeding 600°C (1112°F). Advanced Sealing Solutions : Utilizes high-temperature packing materials like graphite or metal-reinforced seals to main ...

Read More

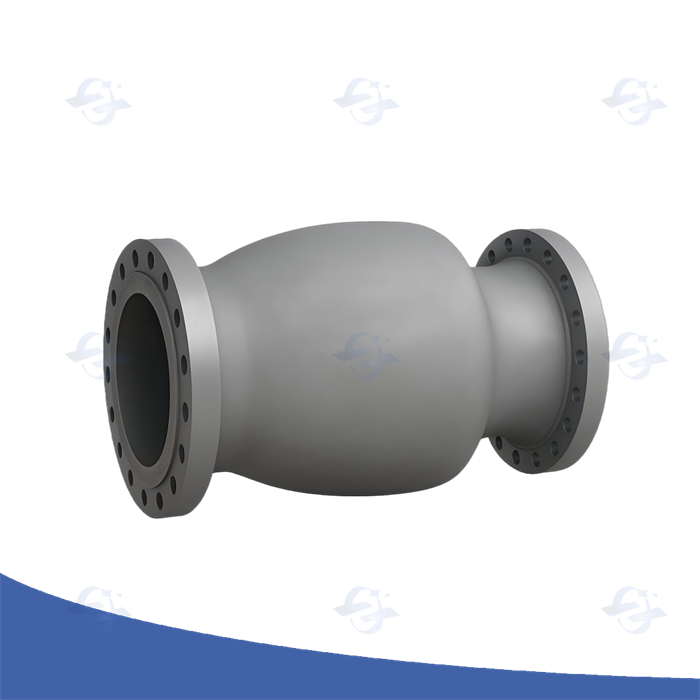

Self-Sealing Flanged Globe Valve – Overview A self-sealing flanged globe valve is a high-performance valve designed to provide reliable flow control and leak-tight shut-off in piping systems. Featuring a flanged connection for secure installation and an innovative self-sealing mechanism, this valve ensures enhanced safety, durability, and operational efficiency. Key Features Self-Sealing Design Incorporates advanced sealing technology that compensates for wear and thermal expansion, maintaining a tight seal without manual adjustment. Flanged Ends Provides robust and leak-proof connections to piping systems, facilitating easy installation and maintenance. Globe Valve Functionality Offers precise throttling and flow regulation through its linear motion disc and seat arrangement. Durable Construction Manufactured from high-quality materials such as stainless steel, carbon steel, or alloy steel for resistance to corrosion, high temperature, and pressure. Compliance with Standards Built to meet industry standards like ASME, API, and ISO for performance and safety assurance. ...

Read More

Throttle Cut-Off Vent Valve – Comprehensive Overview A throttle cut-off vent valve is a specialized valve designed to provide precise flow control and safe venting capabilities within industrial piping systems. This valve combines throttling functionality with venting, enabling operators to regulate pressure, release trapped gases, or safely isolate sections of the pipeline. Key Features and Design Throttle Functionality : Allows controlled flow adjustment, providing fine-tuning of fluid or gas pressure and flow rates. Cut-Off Capability : Ensures complete isolation when required, preventing undesired flow and enhancing operational safety. Vent Valve Integration : Facilitates safe venting of gases or pressure relief to protect system components and maintain process integrity. Robust Construction : Typically manufactured from forged steel, stainless steel, or alloy materials to withstand high pressure, temperature, and corrosive environments. Connection Types : Available with threaded, socket weld, or flanged ends to suit diverse piping configurations. Applications ...

Read More

API Standard Swing Check Valve – Overview An API standard swing check valve is a non-return valve designed in accordance with the American Petroleum Institute’s (API) specifications, ensuring consistent quality, performance, and safety across a range of industrial applications. This valve type automatically prevents backflow by utilizing a swinging disc mechanism that opens under forward flow and closes when flow reverses, protecting pumps, compressors, and piping systems. Key Design Features API Compliance Manufactured to API 6D or API 594 standards for precise dimensional accuracy, performance reliability, and compatibility with global pipeline systems. Swing Disc Mechanism The hinged disc swings away from the seat during forward flow and returns to the closed position under reverse flow or gravity. Material Options Available in carbon steel, stainless steel, alloy steel, or duplex materials to suit various pressure, temperature, and corrosive environments. End Connections Flanged, butt weld, and socket weld ends for seamless integration into pipeline networks. Pressure and Temperature ...

Read More

Axial Flow Check Valve – Overview An axial flow check valve is a high-performance non-return valve engineered to allow flow in one direction while preventing reverse flow through a streamlined axial flow path. Unlike swing or lift check valves, this design utilizes a spring-loaded disc or piston moving along the pipeline axis, minimizing turbulence and ensuring quick closure during flow reversal. This axial motion significantly reduces water hammer and pressure surges, making it a preferred choice in critical, high-velocity applications. Key Design Characteristics Axial Flow Principle The valve disc travels in line with the pipeline axis, guided precisely to maintain a uniform flow profile and minimize head loss. Spring-Assisted Closure A calibrated spring ensures rapid sealing when forward flow decreases, reducing the risk of backflow-induced damage. Streamlined Flow Path Internal geometry is designed for low turbulence and optimal energy efficiency in high-capacity systems. Material Flexibility Available in carbon steel, stainless steel, duplex stainless steel, and high-alloy materials to handle diverse media ...

Read More

Forged Steel Check Valve – Overview The forged steel check valve is a compact, high-strength non-return valve designed to prevent reverse flow in pipelines. Built from forged steel for exceptional pressure and temperature resistance, it operates automatically—opening under forward flow and closing to prevent backflow—protecting pumps, compressors, and other equipment. Key Design Features Forged Steel Body Available in ASTM A105, A182 F11/F22, F304, F316, or other alloy steels, ensuring superior mechanical strength and corrosion resistance. End Connections Flanged Ends – Compliant with ASME B16.5 standards for secure bolted connections. Socket Welding (SW) or Threaded (NPT/BSP) – For compact installations and high-pressure service. Pressure Class Typically offered in ASME Class 800 / 1500 / 2500, suitable for demanding service conditions. Sealing Options Metal-to-metal hard-faced seat or soft-seated designs depending on media and operating conditions. Flow Direction Control Clearly marked with flow arrows to en ...

Read More

Lug Wafer Double Disc Check Valve – Overview The lug wafer double disc check valve is a compact, lightweight backflow prevention device designed for installation between flanges in pipelines. Featuring a dual-disc, spring-loaded design, it ensures quick closure and minimal water hammer while maintaining a low-pressure drop. The lug-style body allows for easy alignment during installation and can be mounted in both horizontal and vertical orientations. Key Design Features Dual Disc Configuration Two independent half-discs mounted on a central hinge pin for rapid closure, reducing reverse flow impact. Spring-Assisted Closure Ensures fast shutoff, minimizing water hammer and providing reliable sealing even in low-flow conditions. Lug Wafer Body Equipped with threaded lugs for precise flange alignment and the option for end-of-line service in certain configurations. Body & Disc Materials Body: Cast iron, ductile iron, carbon steel, stainless steel Discs: Stainless steel, duplex steel, or other alloys for corrosion resistance ...

Read More

Pressure Self-Sealing Check Valve – Overview The pressure self-sealing check valve is designed to automatically prevent reverse flow in high-pressure pipelines by utilizing the system’s own pressure to achieve a secure seal. This valve type is particularly suited for applications where traditional bolted bonnet designs may be less efficient, as the pressure-assisted sealing structure reduces the risk of leakage under extreme operating conditions. Key Design Features Self-Sealing Bonnet Design Uses the internal line pressure to create a tight seal at the bonnet joint, eliminating the need for high numbers of bolting and enhancing sealing reliability under high pressure. Robust Body Construction Materials: Carbon steel, alloy steel, or stainless steel for various temperature and pressure requirements. Pressure Classes: Commonly available in Class 600 to Class 2500. Disc and Seat Arrangement Swing or tilting disc options depending on flow conditions, with hard-faced seating surfaces to withstand erosive service. Standards Compliance Manufactu ...

Read More

Wafer Double Flap Swing Check Valve – Overview The wafer double flap swing check valve is designed for reliable backflow prevention in medium and large diameter pipelines while maintaining a compact and lightweight structure. Its double-door disc design allows for smooth, low-resistance opening during forward flow and rapid closure when reverse flow is detected, minimizing water hammer and pressure surges. The wafer body construction makes it suitable for installations with limited space between flanges. Key Design Features Wafer-Type Body Slim profile for easy installation between standard pipeline flanges, reducing weight and material cost compared to full-bodied check valves. Dual Flap Disc Assembly Each flap operates independently to reduce the force required for opening. Torsion springs ensure quick closing to prevent reverse flow. Low Pressure Drop Streamlined internal passage minimizes turbulence and energy loss. Materials Body: Carbon steel, stainless steel, or ductile iron. ...

Read More

Flanged Butterfly Valve – Overview The flanged butterfly valve is a quarter-turn valve designed for reliable flow regulation and shut-off in pipelines carrying water, air, gas, oil, and other media. Its disc rotates on a central axis, providing quick operation and minimal pressure drop. With a flanged connection on both ends, it offers secure installation and easy maintenance for a wide range of industrial applications. Key Design Features Flanged End Connection Conforms to ASME, DIN, EN, or JIS flange standards for secure, leak-proof pipeline integration. Quarter-Turn Operation 0° to 90° disc rotation allows for fast opening and closing with precise throttling control. Disc & Seat Design Streamlined disc minimizes flow resistance. Resilient or metal seat options to suit various temperature and pressure conditions. Actuation Options Manual (lever or gear-operated) Pneumatic, electric, or hydraulic actuators for automated control systems. Mat ...

Read More

Soft Backing Wafer Butterfly Valve – Overview The soft backing wafer butterfly valve is a compact, lightweight flow control device designed for reliable sealing and quick operation. Featuring a wafer-style body that fits between flanges and a resilient soft seat, it ensures zero-leakage performance for water, air, and compatible industrial media. Its economical design and minimal face-to-face dimensions make it a preferred choice for space-limited installations. Key Design Features Wafer Body Design Fits between standard flanges (ASME, DIN, EN, JIS) and is secured with through-bolts for easy installation. Soft Backing Seat Resilient liner (EPDM, NBR, PTFE, etc.) provides tight shut-off and corrosion resistance, covering both the sealing surface and body bore. Quarter-Turn Operation 0°–90° disc rotation for quick opening, closing, and throttling control. Disc Options Streamlined stainless steel, ductile iron, or coated alloy discs for optimized flow with low pressure loss. Actuation Manual lever or worm gear Pneumatic, electric ...

Read More

Hard Backing LT-Type Lug Butterfly Valve – Overview The hard backing LT-type lug butterfly valve is a heavy-duty quarter-turn valve designed for reliable shut-off and flow regulation in industrial pipelines. Featuring a lug-style body with threaded inserts and a hard seat lining, it offers enhanced mechanical strength, easy pipeline isolation, and superior wear resistance—ideal for high-cycle and abrasive service conditions. Key Design Features Lug-Type Body (LT Design) Equipped with threaded lugs for secure bolt-up between flanges, allowing end-of-line service without downstream piping removal. Hard Backing Seat Metal or hard polymer-backed seat (such as stainless steel, bronze, or reinforced PTFE) provides durability against abrasive or high-temperature media. Robust Disc Options High-strength stainless steel, ductile iron, or coated alloy discs ensure long service life with minimal torque loss. Quarter-Turn Operation Simple 0°–90° rotation for quick opening, closing, and throttling applications. Actuation Flexibility Manual gear operator ...

Read More

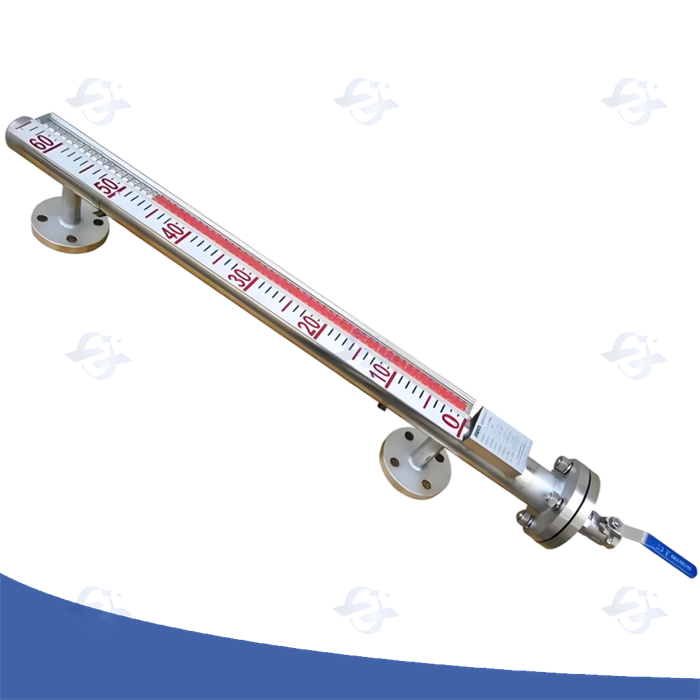

Glass Level Gauges – Overview Glass level gauges are essential instrumentation devices used for visually monitoring liquid levels inside tanks, vessels, and pipelines across various industries. Offering clear, reliable, and real-time indication, these gauges provide operators with critical information to ensure safe and efficient process control. Key Features and Design Durable Glass Tube or Sight Glass Made from high-quality borosilicate or tempered glass to withstand high pressure, temperature, and corrosive environments. Frame and Housing Typically constructed from carbon steel, stainless steel, or aluminum, with protective coatings to resist corrosion. Sealing and Connections Flanged, threaded, or welded ends for secure attachment to tanks or vessels, compliant with industry standards such as ANSI, DIN, and JIS. Optional Accessories Protective covers and shields Lighting kits for enhanced visibility Valve assemblies for isolation and maintenance Reflex or bi-color indicators for improv ...

Read More

Magnetic Flap Level Gauge – Overview A magnetic flap level gauge is a reliable and highly visible liquid level indicator that combines magnetic coupling with color-coded flaps to provide an easy-to-read, real-time display of fluid levels in tanks and vessels. This gauge is especially suitable for harsh industrial environments where direct visual access may be limited or safety concerns prevent open sight glass use. Key Features and Design Magnetic Coupling Mechanism A float inside the tank contains a magnet that moves vertically with the liquid level, actuating a series of external, bi-color flaps through a magnetic field without direct contact with the process fluid. Color-Coded Flaps Typically red and white or red and green flaps alternate to clearly indicate liquid presence (red) versus empty space (white/green), providing intuitive level visualization even from a distance. Robust Construction Gauge body made of carbon steel, stainless steel, or aluminum with corrosion-resistant coatings. Flaps constructed from durable plastic or metal with UV and chemical resistance. ...

Read More

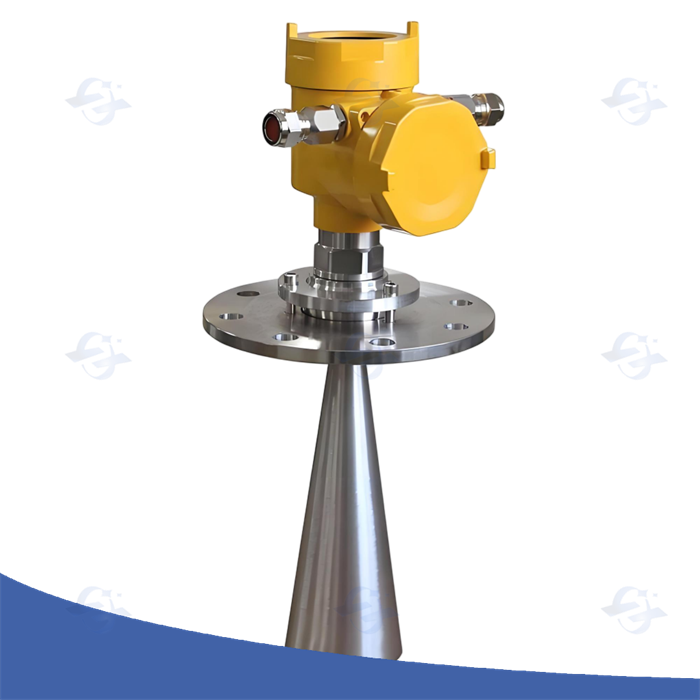

Ultrasonic Level Gauge – Overview An ultrasonic level gauge is a non-contact liquid or solid level measurement device that uses ultrasonic waves to accurately detect and monitor fluid levels within tanks, silos, and open channels. By emitting high-frequency sound pulses and measuring the time it takes for echoes to return from the surface, this gauge provides reliable, maintenance-free level detection suitable for a wide range of industrial environments. Key Features and Design Non-Contact Measurement Ultrasonic sensors measure levels without direct contact, eliminating risks of corrosion, abrasion, or contamination. High Accuracy and Reliability Advanced signal processing ensures precise level readings, even in turbulent or foam-prone surfaces. Versatile Installation Suitable for liquids, slurries, powders, and bulk solids, with mounting options for tanks, vessels, and open channels. Robust Construction Housings made of stainless steel, plastic, or aluminum with IP67/IP68 protection ratings for harsh industrial environments. Wide Measurement Range Effective over distances from a few c ...

Read More

Radar Level Gauge – Overview A radar level gauge is a cutting-edge, non-contact measurement device that uses microwave radar pulses to accurately monitor liquid and solid levels in tanks, silos, and vessels. Renowned for its reliability, precision, and ability to perform under challenging conditions, it provides continuous, real-time level data critical for efficient process control. Key Features and Design Non-Contact Measurement Uses microwave radar signals, avoiding direct contact with the medium, thus minimizing wear and contamination risks. High Accuracy & Stability Delivers precise measurements regardless of dust, vapor, foam, or extreme temperature and pressure variations. Wide Application Range Suitable for liquids, slurries, powders, and bulk solids across many industrial sectors. Robust Construction Housed in durable stainless steel or coated materials with high ingress protection (IP66/IP67), designed to withstand harsh environments. Extended Measurement Range Capable of measuring levels up to 70 meters or more, depending on model and antenna type. Advan ...

Read More

Spring-Loaded Safety Valve – Overview A spring-loaded safety valve is a critical safety device designed to protect pressure vessels, pipelines, and equipment by automatically releasing excess pressure when preset limits are exceeded. Utilizing a spring mechanism, these valves provide reliable and rapid pressure relief to prevent catastrophic failures and ensure operational safety. Key Design Features Spring Mechanism The valve remains closed under normal pressure, held by a calibrated spring. When system pressure exceeds the setpoint, the spring compresses, allowing the valve to open and release excess pressure. Material Construction Bodies and internal components are typically made from carbon steel, stainless steel, or alloy steel to withstand high temperatures, pressures, and corrosive environments. Set Pressure Range Adjustable settings accommodate a wide range of pressure limits according to system requirements and safety codes. Standards Compliance Manufactured in compliance with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, API 526, and ISO 4126 for reliable performance. ...

Read More

Pilot-Operated Safety Valve – Overview A pilot operated safety valve is an advanced pressure relief device designed for precise and stable pressure control in high-pressure and large-capacity systems. Utilizing a pilot valve to control the main valve operation, it offers superior accuracy, reduced leakage, and improved response compared to conventional spring-loaded valves. Key Design Features Pilot Control Mechanism The pilot valve senses system pressure and modulates the main valve opening, enabling quick response to overpressure while maintaining tight sealing during normal operation. High Flow Capacity Suitable for large-scale applications where high flow rates and stable pressure relief are critical. Material Construction Typically constructed from carbon steel, stainless steel, or alloy steel to handle demanding temperature and pressure conditions. Adjustable Set Pressure Precisely adjustable pilot settings allow customization for specific process requirements. Standards Compliance Designed and tested in accordance with ASME BPVC Section VIII, API 526, and ISO 4126 standards. ...

Read More

Bellows Safety Valve – Overview A bellows safety valve is a specialized pressure relief device designed to provide leak-tight sealing in high-pressure, high-temperature, and corrosive environments. Featuring a welded bellows component, it effectively isolates the valve internals from process fluids, preventing leakage and protecting sensitive system components. Key Design Features Welded Bellows Seal A corrosion-resistant bellows assembly separates the valve’s stem and spring chamber from the process media, eliminating leakage and enhancing valve longevity. Material Construction Typically constructed from stainless steel, alloy steel, or other corrosion-resistant alloys to withstand aggressive fluids and extreme temperatures. Adjustable Set Pressure Precisely calibrated to open at designated pressure thresholds, ensuring reliable overpressure protection. Compliance with Standards Manufactured according to ASME BPVC Section VIII, API 526, and ISO 4126, meeting stringent safety and performance requirements. Connection Options Available with flanged, threaded, or welded ends for flexible ...

Read More

Main active: machining below Size: Main Material (forging): The types of BALL Valve we can machine: Most of Forging products: BODY, CONNECTOR, COVER, STEM, SEAT, BALL, FLANGE, SUPPORT PLATE, FORGING WEDGE of Gate Valve, etc... NPS 1/2" to 36" DN 15 to DN900 A105,LF2,F304,F316, Duplex,Super Duplex, F6A,INC.625, INC.825, INC.718, MONEL,TITANUNM,etc... Floating, Trunnion, 3-way, Top-entry, 2-pieces, 3-pieces, Flanged, DOUBLE BLOCK & BLEED, etc ...

Read More

Ball Valve Part: Trunnion The trunnion is a critical internal component of a trunnion-mounted ball valve, providing structural support and stability to the ball during operation. Unlike floating ball valves where the ball is held only by the stem and sealing forces, the trunnion acts as a fixed pivot point that anchors the ball firmly inside the valve body. Function of the Trunnion Support and Stability The trunnion supports the ball at the bottom (and sometimes top), preventing excessive movement during flow and pressure changes, especially in larger valves or high-pressure applications. Reduced Operating Torque By anchoring the ball, the trunnion reduces the stress on the valve seats, allowing smoother operation with less torque required to open or close the valve. Enhanced Sealing Performance Trunnion-mounted designs improve sealing reliability under high pressure and minimize wear on the seats by controlling ball movement. Key Features Typically made from durable materials such as stainless steel or carbon steel for strength and corrosion resistance. Mounted inside the ...

Read More

Ball Valve Part: Stem The stem is a vital component of a ball valve that connects the actuator or handle to the ball, enabling rotational movement to open or close the valve. It transmits the torque applied externally to rotate the ball inside the valve body, controlling flow through the pipeline. Function of the Stem Torque Transmission The stem transfers the turning force from the valve handle, gear, or actuator to the ball, causing it to rotate 90 degrees for on/off operation or partial rotation for throttling. Sealing Interface The stem passes through the valve body and must be sealed properly to prevent leaks. This is typically achieved through packing materials, O-rings, or gland seals. Alignment and Support Provides axial alignment between the actuator and the ball, ensuring smooth, precise valve operation. Key Features Material Usually made of stainless steel, carbon steel, or alloy steel to withstand mechanical stress and corrosion. Stem Types Blowout-Proof Stem : Designed to prevent the stem from being ejected under pressure. ...

Read More